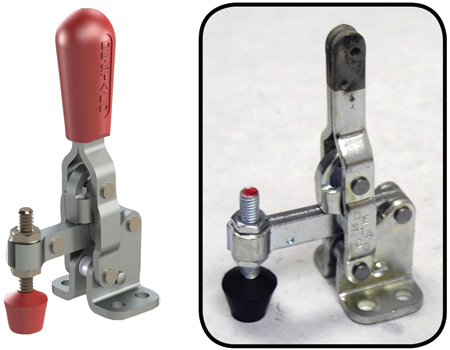

Custom workholding and automation solutions from DE-STA-CO are designed to save users time and make their operations more efficient. Modifications are now available across all product lines and range from grip changes for clamps (shown) to custom turn-key robotic machines.

DE-STA-CO is expanding its custom manufacturing capabilities to provide OEMs and end-users with application-designed productivity tools out of the box. "Customers can work directly with DE-STA-CO engineers to modify any of its clamping, automation and material handling solutions to produce products that are perfectly matched to a specific application," said a company spokesperson.

"Standard tools often do not fit perfectly into a manufacturer's unique production line or OEM machine," said Ken Hagan, Global Product Manager for DE-STA-CO. "In fact, about half of our customers modify the clamps they buy before putting them to use. We have expanded our custom solution programs to take that time-consuming process off of the hands of our customers, letting them focus more on their core business instead of worrying about modifying each new tool purchase."

DE-STA-CO now offers customized solutions and modification services across all of its product lines, including clamps, Robohand grippers, CAMCO indexers and robotic end effectors. The modifications are organized into three levels for each product group to provide guidance for customers:

- Level one modifications include minimal changes like grip substitutions and plating/dipping for clamps; oil/grease changes and alternate mounts for automation products; and non-standard controls, custom mounts and special coatings for material handling equipment.

- Level two modifications include handle/arm extensions or reductions, drilled or tapped arms and custom hooks for clamps; port changes, finishes/plating, stroke adjustment and dial plates for automation products; and detailed concepts for material handling equipment.

- Level three modifications are custom-built designs and product combinations that are developed specifically for each customer application.

Quotes are available in one to two days for level one modifications, three days for level two modifications and five days for level three modifications.

Each custom solution is given its own unique part number to make reordering easy, and to guarantee the same solution is produced the same way for future orders. Working directly with DE-STA-CO engineers and estimators, customers receive drawings of the modified product or solution before it is assembled to make sure application requirements are met.

"At DE-STA-CO, we believe that custom solutions are mutually beneficial," said Hagan. "Our standard products are enhanced as we implement suggestions from more customers. At the same time, by customizing products for our customers, we are saving them time and ensuring that the altered tooling will safely perform for them."

For more information contact:

DE-STA-CO

1025 Doris Rd.

Auburn Hills, MI 48326-2614

888-DESTACO (337-8226)

marketing@destaco.com

www.destaco.com/custom-solutions