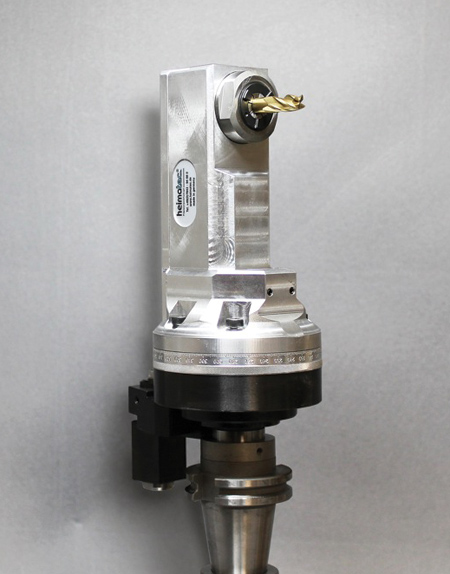

The U-tec flexible adapter system from Heimatec, which is now offered on all of its angle heads, allows various tools to be fixtured in a single base using adapters and a collet nut, reducing inventory requirements and changeover time for the busy shop.

The U-tec flexible adapter system from Heimatec, which is now offered on all of its angle heads, allows various tools to be fixtured in a single base using adapters and a collet nut, reducing inventory requirements and changeover time for the busy shop.

The U-tec flexible adapter system from Heimatec, which is now offered on all of its angle heads, allows various tools to be fixtured in a single base using adapters and a collet nut, reducing inventory requirements and changeover time for the busy shop.

Heimatec has announced immediate availability of its U-tec flexible adapter system on all right-angle heads in the company's line. Models are now available for most popular lines of machine tools in the North American market, according to company President Preben Hansen. "Heimatec plans to include the U-tec adapter system on all angle heads going forward," said Hansen. "This development will especially provide the system's rigidity and quick-change capabilities to users doing deep hole drilling with extended tools."

U-tec is a patented flexible tool adapter system that allows a standard ER output live tool to accept various adapters for different applications. This allows users the ability to have quick changeover of tools on almost any lathe or mill, using a single live tool, without having to commit to a quick-change system on the initial purchase. A face mill adapter, for example, can be quickly positioned into the standard holder, without the need for a completely new base to be installed. This reduces inventory costs as well as changeover time.

"The U-tec system represents a real improvement in lathe and mill/turn tooling design," said Hansen. "U-tec allows great user flexibility, while a polygonal drive system ensures high power transmission stability and faster set-up with no loss in performance or accuracy, because the live tool base remains in position and only the adapter and collet get swapped out."

The collet nuts on the U-tec system have internal threading for rigid mounting. This new tool adapter system enables the actual cutting tool to be brought into closer proximity to the bearing, thus further improving performance in use. This benefit results from the short and compact tool length design. Internal coolant up to 2,000 PSI (140 bar) is provided as standard.

Every adapter in the U-tec system, complete with any necessary clamping nuts and adapters for arbor, Weldon, CAT 40 and CAT 50, is now available in shell mill, face mill, ER extension, side lock, shrink fit, hydraulic and blank styles. U-tec angle heads are compatible with most automatic tool changers, feature 360° manual positioning and include torque arms and a stop block. They are torque rated up to 150 Nm (110 ft-lbs.).

For more information contact:

Preben Hansen, President

Heimatec Inc.

16 E. Piper Lane, Suite 129

Prospect Heights, IL 60070

847-749-0633

phansen@heimatecinc.com

www.heimatecinc.com

IMTS 2016 Booth W-2413