The FACE machine can flat finish medium and large quantities of parts with tolerances in the sub-micron range.

The FACE is equipped with software-supported set-up processes that allow quick changes to production requirements, saving time and making retooling easy.

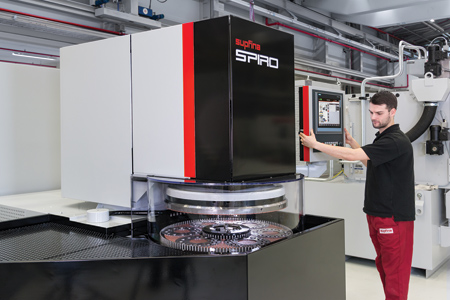

Supfina's new SPIRO fine grinding machine can achieve precise plane parallelism (≤ 1.0 µm) for precision bearings, pump gears, valve plates and more.

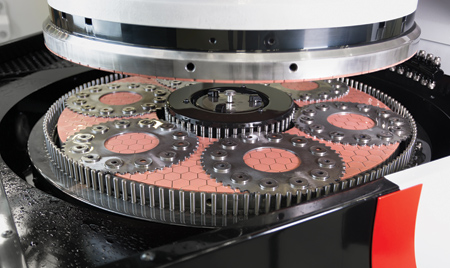

Parts to be finished are loosely placed in "carriers" that pins rotate in an orbiting manner. Machining takes place between two grinding wheels (diamond or CBN).

Supfina will present its new flat finishing and fine grinding machines.

FACE

The FACE is a versatile solution for the flat finishing of parts in a number of fields, including injection technology, transmissions, hydraulics and engines. "Not only can medium and large quantities of parts be finished with the tightest tolerances in the sub-micron range, but the job can be done with the highest reliability and efficiency," said a company spokesperson.

The machine's intelligent design eliminates the need for spindle coolant. "Integrated fire-suppression technology is designed to ensure optimal safety, while the Supfina IQ-Finish process control guarantees reliable and continual compliance with the most demanding quality parameters," said the spokesperson.

The FACE can accommodate workpieces of various sizes: lengths up to 200 mm, diameters up to 200 mm and machining surface diameters up to 150 mm. As many as eight different chucks can be used, and loading can be performed by external robot or gantry systems.

SPIRO

Supfina has added fine grinding to its portfolio of surface finishing systems with its new SPIRO series.

SPIRO eliminates water from the cooling process so there is no chance of contamination. The machine's sturdy base keeps vibration to a minimum, reducing tool wear, while SPIRO's modular, customizable design allows quick tooling changes and easy accessibility. For example, the upper part of the machine swivels, allowing fast loading/unloading of a wide variety of parts.

The SPIRO series is engineered to achieve precise plane parallelism (≤ 1.0 µm) for precision bearings, pump gears, valve plates and more in a variety of materials. "Because they can be processed in batches - up to 20x faster than lapping and with more precision than double disk grinding - costs per part are further reduced," said the spokesperson.

For more information contact:

Andrew Corsini

President and CEO

Supfina Machine Company, Inc.

181 Circuit Drive

North Kingstown, RI 02852-7439

401-294-6600

www.supfina.com

IMTS 2016 Booths N-6299,

N-6394 & N-6398