Vice President Ronald Fasano with the Hanwha XD20H

FANUC control panel

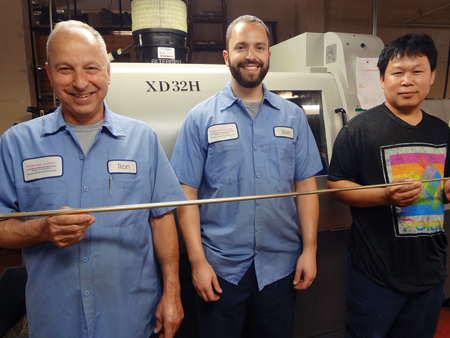

Ronald Fasano, son Ron, and machinist Phonh Sisavat holding a 60" long completely turned part with multiple chuckings

Ron and Mary Fasano

Various parts made at Fasano over its 40+ years in business

Vincent Fasano, son of Ron Fasano, inspecting a part

Fasano Corporation needed to make complicated parts in one operation, which it could not accomplish with its old style cam operated Swiss-type screw machines. "In addition, we wanted to free up the operator's time so he could spend more time setting up jobs instead of loading bar stock and removing chips manually," said Ron Fasano, Vice President, Fasano Corporation. "To do this, we embarked on a search to add new modern manufacturing equipment to our shop.

"The solution at the time was a Swiss-type CNC machine with a sub-spindle that would allow the company to manufacture more complicated parts."

"Once we became comfortable with the CNC machine technology, we knew we needed to grow in this area," continued Fasano. Subsequently, over an eight-year period, Fasano Corporation has acquired six Hanwha Swiss-type CNC screw machines with automatic bar loaders, ranging from 12 mm to 32 mm in diameter capacity. These machines can perform operations such as turning, drilling, tapping, milling, broaching, knurling and threading.

"This solved many of our problems and challenges," said Fasano. "Productivity has increased, reducing or totally eliminating secondary operations. We are now able to competitively take on more complicated work.

"Set-up time is comparable to cam machines; however, similar families of parts only need minor program changes as opposed to a completely new cam changeover. Overall daily yield has improved because the machines run at high speeds with high-pressure coolant and up-to-date cutting tool technology."

Personnel no longer have to clear chips manually. Parts do not have to be separated from the turnings because they are transferred from the machine's sub-spindle to a parts chute, onto a conveyor and then into a basket. A vacuum part recovery unit was purchased for small part recovery to allow collection of miniature lightweight plastic parts.

The Hanwha machines are capable of running up to 10,000 RPM. Added accessories on all machines include an HP Cool Tech high-pressure coolant delivery system and a Filter Mist system to provide a healthier environment for employees. Fasano Corporation extracts cutting oil from all of the chips that leave the facility. The oils are then reused and the metals are sold as scrap.

Fasano Corporation manufactures close tolerance turned parts to .0002". Materials typically machined at Fasano Corporation include stainless steel, drill rod, BeCu, aluminum, titanium, a variety of aircraft alloys including Stellite, Inconel and all types of plastics. Industries served include electronics, aerospace, automotive and medical.

Machine inventory at Fasano Corporation includes two Hanwha SL12H, one Hanwha XD12H, two Hanwha XD20Hs and one Hanwha XD32H. Fasano Corporation has a full line of inspection capabilities, including comparators, microscopes at every work station, indicator micrometers, Johnson thread gauging, calibrated gauge block sets and master round gauges.

Fasano Corporation, Inc. was founded in 1972 by Albert and Ronald Fasano (father and son) for the purpose of producing precision Swiss screw machine parts. They began with only six Tornos Swiss-type screw machines. President Albert Fasano has worked in the machining industry for over 70 years, retiring at the age of 90. Ronald Fasano, Vice President, is an expert machinist and cam maker with over 50 years of experience. He holds a bachelor's degree in industrial engineering from Roger Williams College. Continuing in the tradition, he is now joined by his two sons, Ronald and Vincent, both educated in the manufacturing and engineering field.

Mary Fasano, Ron's wife and company bookkeeper for over 30 years, recently implemented Realtrac ERP job shop management software to update the way in which jobs are processed, from estimation of jobs to final product to accounting. Routers are issued for all jobs, and employees sign off to show accountability for operations performed. Material and parts inventories are tracked more easily, with associated material certifications readily accessible. Certificates of conformance are attached to every job.

All incoming material has been inspected and certified by Fasano Corporation's suppliers. Certifications are also required from firms on any outside work to be done, such as heat treating and plating.

"We are a small, family-owned machine shop with a reputation for taking pride in our workmanship," said Fasano. "Our specialty has always been high quality, close tolerance, small precision work. We take the time to do the job right the first time. We work as a partner with our customers, vendors and employees."

Fasano Corporation is ISO 9001:2008 certified.

For more information contact:

Fasano Corporation

333 Wellington Ave.

Cranston, RI 02910

407-785-9646

www.fasanocorp.com

Hanwha Machinery America, Inc.

9750 South Oakwood Park Drive

Franklin, WI 53132

414-421-2300

www.hanwhamachinery.com