A part used in the semi-conductor industry is machined utilizing the Hainbuch Mando I.D. workholding feature of the centroteX system

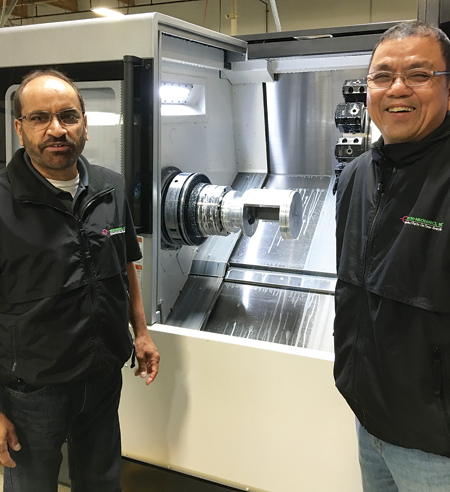

(l-r) Swan Rai, Section Manager and Senior Engineer, and Phi Duong, Associate Engineer and Senior Machinist, Micro-Mechanics Turning Department, inspect a part machined with the Hainbuch centroteX system

Chris Borch, CEO, Micro-Mechanics Inc.

The traditional approach to multiple parts manufacturing - applying available technology to individual applications - was never going to work for Chris Borch. The Founder and CEO of Micro-Mechanics realized early on that success in the global market requires a holistic approach based on delivering customer satisfaction through adherence to three key qualities: product perfection, fast delivery and cost competitiveness.

Micro-Mechanics, which began in 1983 with a small shop in Singapore, has expanded into an international resource for short-run, high-precision components serving key customers in the aerospace, medical, instrumentation and wafer fabrication industries. Having established four manufacturing facilities in Asia producing such complex configurations as specialized assembly tools for the semiconductor industry, the publicly held company made a strategic decision to establish a facility in the United States and seven years ago acquired a contract manufacturer located in Morgan Hill, CA.

Borch commented, "We saw our California facility as a Tier 1 supplier to the semiconductor, medical and high-tech instrumentation industries, and we knew right away that, in order to achieve that goal, we would be unable to utilize the existing equipment. Also, given the costs involved in a California location, we understood the necessity for developing full 24/7 machining capability."

The first step involved investing in a state-of-the-art fully palletized system for parts handling and developing a library of proprietary tooling and fixtures capable of eliminating up to 95% of the set-up time required by conventional equipment.

Borch noted, "Time is a critical factor at every level throughout our operation, both from our customers' point of view and from our own manufacturing philosophy. Our `24/7 Machining' program enables us to meet customer orders in a timely manner, while at the same time maintaining the efficiencies that optimize our capabilities and keep us profitable."

"24/7 Machining" references 168 hours of continuous production per week. This involves 160 hours, or 95% spindle utilization and 8 hours dedicated to regular and preventive maintenance. Borch explained, "24/7 Machining was developed as a cost-competitive solution for the high-mix, low-volume production demands of the customers we serve."

In re-engineering the California facility to meet Micro-Mechanics' exacting standards, it was necessary to develop a new production strategy and to assemble a team capable of working together to achieve present goals and accommodate future evolution. The participants selected to work with Micro-Mechanics on the design and implementation of the system were chosen for their individual capabilities and, equally important, their ability to integrate their products and individual areas of expertise into a unified system.

Borch stated, "We began by defining the types and quantities of the parts we would be manufacturing. Our customers typically order in small batches to minimize their inventory and obsolescence risk - generally fewer than 25 pieces. The parts are primarily aluminum and sized to fit within a prismatic 28-inch cube or a rotational blank 28 inches in diameter by 28 inches in height. Working with Gosiger Machine, we chose an Okuma lathe equipped with Sandvik tooling that enabled us to integrate radio frequency identification (RFID) on our toolholders. We integrated both standard and specialized tooling and, to save time, we are able to change and preset tools offline."

The need for high precision, the minimal number of parts machined at any one time, the variety of part configuration and the 24/7 spindle utilization goal made it clear that an extremely versatile workholding system with quick-change capability was called for. The system selected was the HAINBUCH centroteX system, which would not only accommodate the wide variations in workpiece size, but would allow quick and accurate changeover between I.D. and O.D. machining.

According to Jim Woods, President of HAINBUCH America Corp., "In analyzing the customer's requirements, we realized early on that this was a great application for HAINBUCH's flexible workholding platforms. Basically, we were being called on to deal with a myriad of parts, locating on both outside and inside diameters and ranging in size from 15 mm to 300 mm, while minimizing changeover times and complexity."

HAINBUCH's centroteX system facilitates the fast and easy changeover of the entire workholding device, thereby increasing the range of part diameters that can be turned and extending the capability of the lathe in terms of size and processes.

The centroteX system is based on a precision machined adaptor/flange plate equipped with a bayonet coupling. This in turn accommodates a variety of chucks and holding devices of different sizes and configurations that are easily connected and locked by six simple fasteners. The changeover time can be as little as five minutes. Changeover to I.D. clamping or a three-jaw adaptation can be done in two minutes, and collets can be changed in 10 seconds, all with 10-micron repeatability.

To assist with heavy clamping devices, HAINBUCH's patented Monteq mounting aid can be affixed to a suspension bar on the lathe. The spring-mounted attachment speeds the changeover, and gradations on the device assist in the simple and accurate alignment of the horizontal axis. Non-threaded, quick-action bolts secure the workholding device for loading or removal.

For the Micro-Mechanics system and other installations requiring multiple workholding configurations, a clamping device storage unit services the lathe, holding chucks or other equipment when not in use. The unit moves on heavy-duty casters and incorporates a retractable hood to shut out contaminants.

Tom Chambers, HAINBUCH America's West Coast Regional Sales Manager, commented, "In all of the Micro-Mechanics changeover scenarios, the accuracy of the system obviates the need for any additional alignment or routine first-piece inspection, and all components repeat to 6 microns or less. Also, the changeovers are accomplished with simple hand tools and require minimal machine operator training. This contributes greatly to maximizing spindle uptime, even when changing over several times per shift.

"Traditionally, I.D. clamping has represented a challenge when it comes to fast changeover. HAINBUCH's Mando Adapt allows the machine operator to quickly and easily reconfigure the workholding in less than two minutes while meeting full accuracy demands."

The scope of the system and the multiple components involved presented a significant challenge to all suppliers involved, as well as to Borch's team at Micro-Mechanics. It quickly became apparent that the most efficient way to "prove" the system would require a full-scale demonstration. Over a period of three months, all participants cooperated in developing a working prototype in Charlotte, NC, at the Partners In THINC facility. Due to the skill and outstanding collaboration of the engineers and operations people from Gosiger, Okuma, HAINBUCH and Micro-Mechanics, the demonstration was accomplished on schedule and met or exceeded all desired performance standards.

According to Borch, "The key to the success of the system is the realization that we were not dealing with a refinement but with an original concept and that we can and do employ a verification system prior to running any parts. All of the components included were built for integration, as opposed to standalone performance. We continue to demonstrate that, when people have the right tools, anything is possible."

Jim Woods concurred: "It is extremely refreshing to work with Chris and be part of his compelling vision for modern production processes. Projects such as this stimulate the imaginations and ignite the passions in our young engineers and other team members who are revitalizing the competitive advantages of American manufacturing, as well as customers who are discovering how innovative manufacturers like Micro-Mechanics are defining solutions that respond directly to their needs."

Borch agrees. "During the last 30 years, too many good manufacturing jobs have left the United States. Although there are a host of reasons for this exodus, one of our big goals at Micro-Mechanics is to offer customers in the U.S. a compelling alternative to overseas manufacturing. Along the way, we also hope to create great jobs for our people."

For more information contact:

Micro-Mechanics, Inc.

465 Woodview Ave

Morgan Hill, CA 95037

408-779-2927

mmusa@micro-mechanics.com

www.micro-mechanics.com

HAINBUCH America

W129 N10980 Washington Dr.

Germantown, WI 53022

800-281-5734 / 414-358-9550

sales@hainbuchamerica.com

www.hainbuchamerica.com