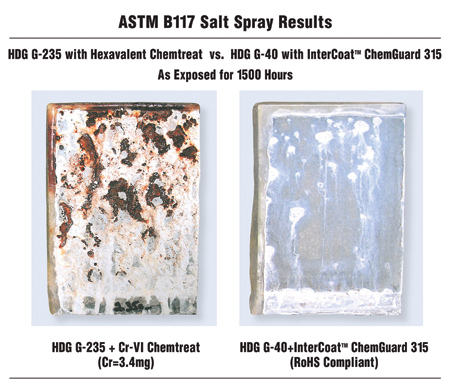

ASTM B117 salt spray test results, performed on HDG G235 with hexavalent chemtreat vs. HDG G40 with InterCoat ChemGuard 315, as exposed for 1,500 hours. The RoHS compliant coating applied by Chemcoaters is made with trivalent chrome vs. hexavalent chrome, a known carcinogenic.

Chemcoaters, Inc., a green coil coater based in Gary, IN, has addressed EQ (Equivalent Coating) with testing. "G40 hot dip galvanized with Intercoat ChemGuard outperformed G235 in tests," said Director of Sales & Marketing Mike Tieri.

"An example is that for 16 gauge coil (0.056" specifically), the zinc coating to a G30 thickness is currently adding $1.90 CWT," said Tieri. "To apply Chemcoaters' Intercoat ChemGuard to G30 is no more than $4.00 CWT. Since G30 is commercially available from many sources, it means service centers, OEM's and processors can use a lighter and less-expensive zinc coating thickness, have a metal product that is considerably easier to form and shape, reduce SKU's, increase inventory turns, increase corrosion resistance and save money immediately," Tieri said. He further noted that this example is not always applicable, given the size of the coils supplied to Chemcoaters.

The InterCoat ChemGuard product can also remain bare, be painted or welded, plus it is RoHS compliant and can be tinted in a spectrum of colorations.

Chemcoaters, Inc. is a supplier of various coil coatings and cleaning services for the coiled metals market. The company's patented InterCoat ChemGuard 300 coating is formulated with trivalent chrome vs. hexavalent chrome, making it environmentally friendly in all building, architectural, transportation and consumer appliance applications. InterCoat ChemGuard 300 coating is designed with corrosion resistance, as well.

For more information contact:

Mike Tieri

Director of Sales & Marketing

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

877-411-2905

miket@chemcoaters.com

www.chemcoaters.com