Absolute Tongtai SH-5000P

Absolute Quicktech i-42-robo

Absolute AccuteX AL-600SA EDM

Absolute Machine Tools will demonstrate machine tools and EDM machines to meet a wide variety of manufacturing needs.

You Ji VTL-1200ATC+C VTL

The You Ji VTL-1200ATC+C is a 49" table / 63" swing vertical turning lathe with full C-axis and live milling for heavy duty turning and milling of large sized workpieces. This heavy-duty VTL weighs in at 72,600 lbs. and features a rigid vertical column and a Meehanite casting base which is heavily ribbed for reduced thermal distortion and vibration dampening. The machine has a symmetrical base and column design.

The X and Z axes are a box way design with Turcite B applied to mating surfaces and hand scraped for precise fit and alignment. The ways are completely enclosed and a forced lubrication system assures high precision. This rigid system enables heavy duty machining and high precision. The Z-axis is a large 9" square ram made from cast steel that is extremely rigid even when extended the full 35.4". The precision class 3 ballscrews are driven directly by the servomotors, eliminating belts or gears for high precision. The cross rail is moveable on box ways and is hydraulically clamped for rigidity and accuracy.

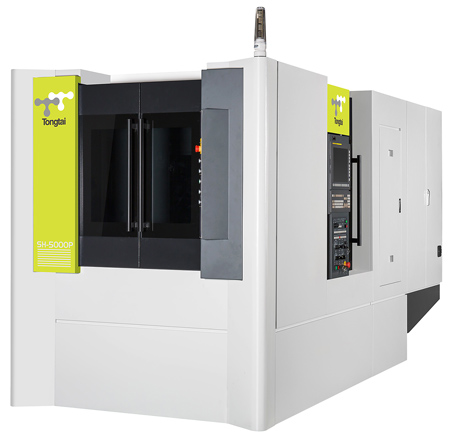

Tongtai SH-5000P High Speed HMC

The new SH-5000P horizontal machining center (HMC) from Tongtai was developed for mass production line formation. The new 90" wide compact machine has a 35% smaller footprint than the previous model.

The Tongtai SH-5000P HMC has an XY traveling column type design where the pallet moves in Z. The APC unit, located in front of the machine, provides easy access and slashes idle time. The APC is a rotary type pallet changer and it exchanges the pallets in only 7 seconds. For pallet rotation in the machining envelope, a full contouring B-axis precisely indexes the pallet every .001° and a hydraulic clamping mechanism is used to clamp the pallet in place for repeatability. The B-axis is high speed, with 90° index time of 0.76 seconds.

Quicktech S-32 ATM 9-Axis Twin Spindle

The compact, high-precision Quicktech S-32 ATM 9-axis twin spindle mill/turn center combines integral motor main- and sub-spindles with a 190° B-axis milling head and a fast automatic toolchanger to maximize output of small, complex parts. Quicktech machines are distributed in North America exclusively by Absolute Machine Tools, Inc.

Steve Ortner, President and Owner of Absolute Machine Tools, said, "These compact, versatile machines enable manufacturers to produce precise, complex smaller parts quickly, with the added benefits of the accuracy and consistency. This machine is ideal for medical applications, for example."

The S-32 ATM has 9 axes in total, including two turning spindles and a 190° B-axis milling spindle, serviced by a 24-tool (36 tool optional) arm-type automatic changer. Six fixed gang-type I.D. turning tools at sub-spindle result in a total capacity of 30 tools (42 optional). The machine's compact 3,750 mm (150") x 2,175 mm (87") x 2,025 mm (81") dimensions (including chip conveyor) promote efficient use of manufacturing floor space.

Quicktech i-42 ROBO and i-60 ROBO 4-Axis

Quicktech i-42 ROBO and i-60 ROBO 4-axis mill/turn centers feature integrated 6-axis Mitsubishi robots for fast, automated loading and unloading of medium diameter (i42: 42 mm/1.68", i60: 60 mm/2.36") bar stock. In addition to carrying out highly productive turning, the machines can perform complex milling with standard live tools. An optional 360° B-axis further extends milling capabilities.

The i-42 ROBO and i-60 ROBO machines operate in 4 axes (5 with the optional B-axis), with a 15-HP high-torque turning spindle that features C-axis capability, a 2-HP live tool milling spindle, and capacity for 17 tools (23 with B-axis). A standard DIN-173-42B collet chuck provides capacity for 42 mm bar, while an optional with a 60 mm collet or 6", 3-jaw chuck offers 60 mm bar capacity.

LICO LNTS Screw Machine, LNDD Mill/Turn Center

Absolute Machine Tools will demonstrate two LICO machines-a CNC screw machine and a mill/turn center.

The LNT-42S-S4, has a 42 mm spindle with four heavy-duty dovetail and gib-design cross slides that can overlap up to five tools in the cut at one time. This screw machine is ruggedly built and capable of using either form tools or standard carbide insert tools with each slide having a full 2-axis servo-controlled travel.

A turret-mounted pickoff spindle is standard and the base machine model comes equipped with gang slide backworking, dual high-pressure oil pumps, chip and part conveyors, and toolholders for all positions. A modular eight-position backworking turret is optional. The main turret uses VDI-30 live tooling and comes with four live tool holders. The LNTS platform is available in four bar capacity sizes-36 mm, 42 mm, 51 mm and 65 mm-all with a maximum turning length of 170 mm. All LNTS models can be ordered with an optional Y-axis gang tooled cross slide for both static and live tools.

The second LICO in the booth is an LNDD-series machine. The LND-65D-S3 is an 11-axis mill/turn center that can often produce parts faster than conventional twin spindle, multi-turret machines with up to five tools in the cut simultaneously. This machine has a bar capacity of 65 mm (2.56"), maximum turning length of 475 mm (18.7") and employs independent 2-axis cross slides that can overlap each other and the turret.

Johnford DMC LH Series Bridge Mill

Johnford DMC LH Series double-column moving table bridge mills join the expansive lineup of Johnford double column and sliding double column machining centers, bringing capacity and affordability to large part machining. The LH series features 110" (2800 mm) in Y and 122" (3100 mm) to 244" (6100 mm) in X in 39.4" (1 meter) increments. Standard Z axis travel is 32" with 42" and 60" optionally available.

The Johnford DMC-3100LH, 4100LH, 5100LH, and 6100LH all feature rigid box ways in Y and Z and Schneeberger roller ways in X for high load carrying capacity. Heavy duty 35 HP (50 HP opt.) 2-speed gearbox driven spindles provide heaving cutting power and torque. The standard 40 tool ATC (60, 80, 120 opt.) provide fast tool changes.

AccuteX AL-600SA CNC Wire EDM

AccuteX's new AL-600SA CNC wire EDM machine will debut at IMTS 2018. To celebrate the occasion, Absolute has partnered with ESPRIT CAD/CAM software and Marposs probing systems and will host a demonstration showing the solid model and part transfer all the way through the complete wire EDM process and how the application is accomplished easily, efficiently and accurately.

The AL-600SA moving-table model will be fully equipped with 6-axis capability, PCD cutting circuit and AccuteX's exclusive linear shaft motors. These motors were designed and built fully in-house specifically for AccuteX wire EDM machines. "This concept ensures world-class precision and performance with its maintenance-free design, 10% faster cutting, HIWIN linear guideways, 0.000004 inch Fagor glass scales and 64-bit processing," said Ortner.

Accuracy is achieved at +/- 0.00012" (0.003 mm) and repeatability +/- 0.00008" (0.002 mm). MST-II Micro Sparking Technology comes standard for surface finishes down to 5 Ra µ in in five passes.

The AL-600SAi comes standard with AccuteX's patented fully-annealing automatic wire threading (AWT) with the ability to perform submerged machining up to 11.81" (300 mm) deep. Travels are 23.62" X-axis, 15.74" Y-axis, 11.81" Z-axis, and 3.94" U and V axes. Maximum workpiece size (XYZ) is 38.97" x 24.41" x 11.61" (990 mm x 621 mm x 295 mm) with a max workpiece weight of 2,450 lbs. (1,113 kg.)

Nexturn SA-32PYII Swiss Lathe

The Nexturn SA-32PYII Swiss lathe is a 32 mm machine that comes standard with an exchangeable rotary synchronous guide bushing. This new model allows changeover from guide bushing to non-guide bushing depending on the application and material.

The lathe features up to 8 total axes (Z1, X1, Y1, Z2, X2, Y2, C1, C2) and up to 25 total tools. Machining capacity is 32 mm on the main and sub-spindle, and 210 mm (8") maximum turning length with guide bushing and 60 mm (2.36") without the guide bushing. Nexturn Swiss machines use FANUC controls. The main spindle is a 10 HP, 8000 RPM built-in motor spindle.

For more information contact:

Absolute Machine Tools, Inc.

7420 Industrial Parkway

Lorain, OH 44053

800-852-7825 / 440-960-6911

sales@absolutemachine.com

www.absolutemachine.com

IMTS 2018 Level 3, Booth S-338536