The Dormer Shark Taps are color coded for material suitability.

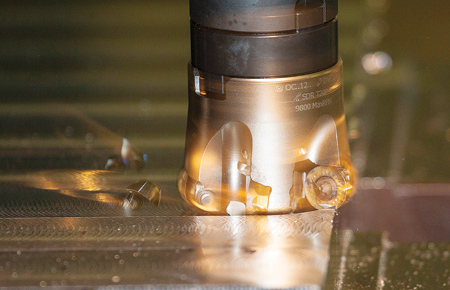

The versatile Pramet ISOD05 offers 54 options in a single cutter.

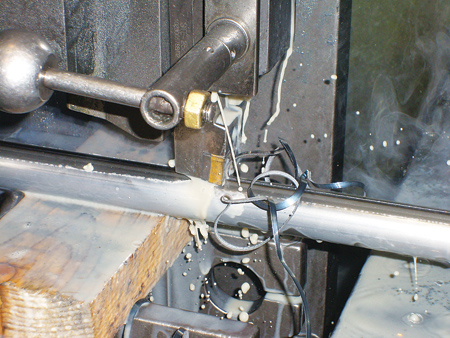

The Pramet indexable scarfing products.

The Precision Twist Drill R10A is manufactured to NAS 907 standard.

The selection of Precision Twist Drill rotary burrs.

The Shark Line of Dormer taps are material-specific taps offering high performance and process security. The tools are easily recognizable by their color ring coding on the shank which identifies material suitability and supports quick and easy tool selection.

The Yellow Shark is for structural, carbon and low alloy steels; Red Shark for alloy steels; Blue Shark for stainless steels and White Shark for cast irons.

The Shark Line is available in standard ANSI shank and square with DIN overall length, offering extra reach and compatibility with Inch Standard Tap Holding. "The taps' advanced geometry provides a reduction in axial forces and torque compared to conventional taps," said a Dormer spokesperson. "This ensures problem-free threading of blind and through holes."

All Shark taps are manufactured from a powder metallurgy tool steel. The spiral flute taps (Yellow, Red and Blue Shark) incorporate a special edge treatment to increase strength and reduce the chance of micro-chipping on the cutting edges.

An internal coolant option (White Shark Form E taps) improves tool life, provides optimum chip evacuation when threading short chipping materials and is beneficial in horizontal blind-hole machining.

Pramet ISOD05 Cutter

Further expanding indexable milling, this new Pramet cutter adds an adaptable option to support a wide range of insert shapes and operations from roughing to finishing.

The ISOD05 cutter has a universal pocket capable of carrying octagonal, round and square inserts.

Available in a wide range of diameters from 1.500" - 5.0", the tool can perform face milling, shoulder milling, slotting, plunging and ramping in steel, stainless steel, cast iron and possibly suited for non-ferrous materials and high-performance alloys.

Pramet has added a range of octagonal (OD), round (RD) and square (SD) inserts. The OD insert has eight cutting edges for low cutting forces, promoting an economical option for face milling, while the RD inserts are suitable for high feed roughing, shallow profiling and ramping.

The SD inserts have four cutting edges and offers a 90° option for square shoulder milling, providing high depths of cut up to 0.394" (10 mm). All types of inserts have the same radial and axial positions of edges.

Pramet Scarfing Inserts

Dormer Pramet has a comprehensive selection of scarfing inserts within the Pramet indexable range.

Scarfing is a specific metalworking technique which uses indexable cutting tools to clean excess weld, both internally and externally, during the tube production process. The Pramet inserts are suitable for carbon steel, corrosion-resistant steel and heat-resistant materials.

The latest scarfing line includes more than 50 products using Pramet T9335 grade, which is specifically designed for machining steel and stainless steel under very harsh conditions. The Pramet T9335 grade consists of stable and highly reliable substrates with abrasion resistant coatings.

Included in the more than 50 Pramet branded items are SNMX 251224-Rxx, SNMA 250924-Rxx, SNMX 15, SNMX 19 and PSR.

Precision Twist Drill

The Precision Twist Drill brand has a full range of drilling tools manufactured to National Aerospace Standards (NAS).

NAS 907 HSS and HSCo standard drills are available in stub, jobber and aircraft extension lengths and are made from HSS (bright or steam oxide) and HSCo (bronze oxide) substrates. Fractional, wire gauge, letter and metric size ranges are available. Select series available to this standard include the R10A, R10B, R10CO, R88CO, 500-12, CO500-12 and relevant sets.

NAS 965 HSS threaded hex shank standard drills are available in stub, short and long lengths. All are manufactured with 1/4-28 UNF threads and 5/16" wrenching flats. Standard diameters are available in fractional, wire gauge, and letter ranging from 0.0980" to 0.2500".

Carbide Burrs

The Precision Twist Drill brand continues to expand with the addition of Carbide Rotary Burrs. This new range consists of two new material specific geometries. The Double Cut (DC) geometry is suitable for machining steels, while the Aluminum Cut (FM) is for machining aluminum and other non-ferrous materials. Available in a variety of shapes, both offer improved operator control and generate less temperature.

"Available with Plainend (type A), Burend (type B), Millend (type C) and Drillend (type D), these designs will reduce splintering and improves the quality and finish at the entry and exit surfaces," said the spokesperson.

Union Butterfield FlashTap

Union Butterfield has been serving tapping applications since 1895. The Union Butterfield cutting tool brand offers the FlashTap program to provide a carefully analyzed selection of semi-special tap products offered to help meet tap delivery requirements. Dormer Pramet carries stock of both standard and semi-special taps.

For more information contact:

Dormer Pramet

2511 Technology Drive

Suite #113/#114

Elgin, IL 60124

847-783-5700

www.dormerpramet.com/imts

IMTS 2018 Level 3, Booth W-432432