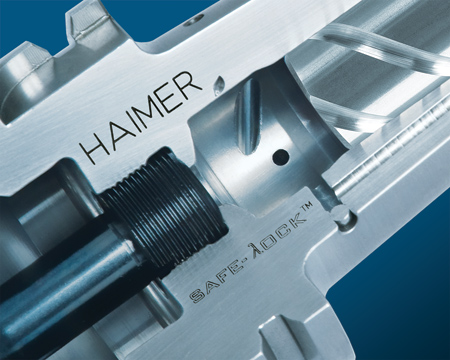

Safe-Lock increases process security and enables a higher metal removal rate.

HAIMER USA has announced two additional Safe-Lock partnerships with cutting tool manufacturers in the U.S.

CGC/Gorilla Mills, HAIMER USA Partner

CGC Cutting Tools, a U.S. cutting tool manufacturer, and HAIMER USA, have signed a U.S. licensing agreement for HAIMER's patented Safe-Lock anti-pullout system. CGC's Gorilla Mill end mills are now available with the HAIMER Safe-Lock system within the U.S.

Safe-Lock was designed to prevent the rotation or pull-out of round cutting tools during heavy machining applications. Its design utilizes a positive form locking mechanism in combination with the high torque shrink fit clamping. The combination of a symmetrical locking tool design with high concentricity and balance of the Safe-Lock system results in a vibration-free machining process.

"CGC Cutting Tools places great importance on the performance of its Gorilla Mill end mills in machine tools, striving to reduce chatter, decrease cycle times and extend tool life through the cutting-edge design of its end mills," said a CGC spokesperson. "Aptly dubbed 'Weapons of Mass Production,' the Gorilla Mill was designed with a variable flute and index design that is recommended for aggressive machining applications. While the end mills are built for high speeds and aggressive cuts, the higher helix angles and increased cutting forces also have potential to lead to tool pull-out. Based off of customer feedback, CGC researched a solution that would enable its Gorilla Mill end mills to realize the full potential in terms of cutting tool speeds while ending the risk of tool pull-out. This ultimately led CGC to partner with HAIMER and its Safe-Lock system as an official U.S. licensee."

"We welcome CGC/Gorilla Mill as an official U.S. Safe-Lock Licensee," said Brendt Holden, President of HAIMER USA. "The Safe-Lock system was specifically designed for aggressive machining applications and high speeds, as were the Gorilla Mill end mills. It is for this reason that I believe that the Safe-Lock system is a particularly good fit for these end mills and will be well received by Gorilla Mill customers across the U.S."

CGC President Kevin Cranker said, "HAIMER is obviously the number one name in pull-out protection with its Safe-Lock system; CGC/Gorilla Mill is very excited to have this in our arsenal."

Core Cutter New Safe-Lock Licensee

"Core Cutter is committed to continually meeting its customers' needs, with superior product quality and outstanding customer service," said a Core Cutter spokesperson. "The focus on continual improvement in all aspects of carbide tool manufacturing motivated us to design better tools, allowing greater speeds and increased machining efficiency. However, we discovered that the increased metal removal rates can lead to a potential pull-out of the cutting tool during aggressive machining due to higher helix angles and increased cutting forces. Core Cutter sought out a solution that enables the full realization of its tools' potential cutting speeds. The research, along with customer feedback, led Core Cutter to partner with the HAIMER Safe-Lock system technology."

Core Cutter, LLC is a family owned and operated carbide cutting tool manufacturer located in Farmingdale, ME. Core Cutter manufactures a variety of standard, modified and custom-made solid carbide tooling with fast turnaround from print to ship. Offering a wide variety of carbide cutting tool services including: design, manufacture, inspection, edge preparation, tool coatings and more.

"We welcome Core Cutter as a U.S. Safe-Lock licensee," said Brendt Holden, President of HAIMER USA. "The high quality seen in Core Cutter's end mills lends itself perfectly to the Safe-Lock design. I am confident that Core Cutter's customers will very much appreciate the added security of this technology and its innate ability to increase their productivity on the shop floor."

For more information contact:

HAIMER USA

134 E. Hill Street

Villa Park, IL 60181

630-833-1500

haimer@haimer-usa.com

www.haimer-usa.com

CGC Cutting Tools

W226N735 Eastmound Dr.

Waukesha, WI 53186

866-888-9600

orders@gorillamill.com

www.gorillamill.com

Core Cutter, LLC

362 Maine Avenue

Farmingdale, ME 04344

207-588-7519

sales@corecutterusa.com

www.corecutterusa.com