Grinding Wheel Technology Provides Precision, Productivity

August 1, 2018

"Meister's new hybrid-bonded long-lasting precision dressing tools reduce process variability while improving quality and productivity of grinding processes," said a company spokesperson.

"Meister precision is meeting the challenges of the fuel injection and bearing industries where internal dimensions are ever diminishing and materials are becoming more exotic. And on the large side, Swiss quality external vit CBN and diamond wheels up to O1225 mm (approximately 4 ft.) are now manufactured in and delivered from the USA," said the spokesperson.

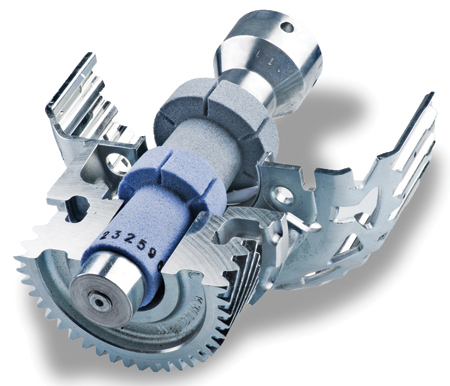

In this gear box cutaway two wheels mounted on one arbor are simultaneously grinding multiple bores and faces.

Meister Abrasives, developer of advanced vitrified CBN and diamond superabrasive grinding wheels, will be displaying innovative products that can be custom-tailored to provide users with enhanced manufacturing quality, precision and productivity. Exhibiting alongside Meister Abrasives will be sister company Alfons Schmeier GmbH & Co. Both companies are divisions of Abraxos Holding AG, Switzerland.

The exhibit will include:

- HPL anti-friction abrasive products formulated to eliminate part burning while maintaining enhanced grinding productivity

- Hybrid-bonded long-lasting precision dressing tools that can reduce process variability while improving quality and productivity of grinding processes

- New double-disk fine-grinding wheel solutions customized for grinding ultra-flat and parallel surfaces

- Big Wheels - Swiss quality large vit CBN and diamond abrasive wheels, up to O1,225 mm (approximately 4') in diameter, manufactured in and delivered from the U.S.

- Custom tailored grinding and dressing solutions targeted to resolve critical issues facing a broad range of industries, including automotive, fuel injection, aerospace, bearing, medical, energy and semi-conductor manufacturing.

Meister Abrasives applications engineers will be on hand to discuss how to improve the performance of grinding processes.

For more information contact:

Meister Abrasives USA, Inc.

201 Circuit Drive

North Kingstown, RI 02852

401-294-2530

sales@meister-sbrasives-usa.com

www.meister-abrasives-usa.com

IMTS 2018 Level 3, Booth N-237341

< back