Available in 25.4 mm or 36 mm, the new SwissDECO G version has up to 38 tool positions, 27 of which can be live tools.

Designed for small workpieces requiring high precision, the SwissNano's kinematics enable the machine to produce two thirds of watch movement components, from the simple to the most complex.

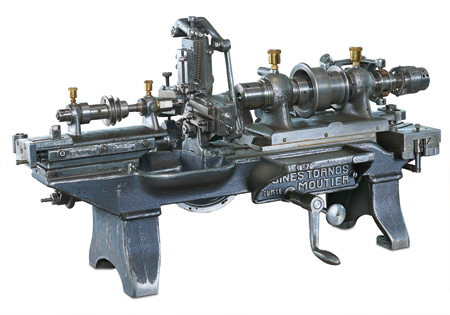

A 100-year-old lathe made in Switzerland, the Tornos No. 20 tells the story of the history of Tornos and demonstrates the revolutionization and innovation of the brand since then.

Swiss machine tool manufacturer Tornos will be exhibiting technologies from single-spindle to multi-spindle, along with its own Industry 4.0 software, TISIS. Six machines will be displayed in Tornos' booth: SwissDECO 36; MultiSwiss 6x16; Swiss GT 26; SwissNano with an American flag decal; the Esco NM6 Flexi; and an original 100-year-old Swiss lathe, No. 20, made in 1917. Three Tornos products will also be represented in Tornos' distributor, Methods Machine Tools' booth: MultiSwiss 8x26; SwissNano; and Swiss DT 26.

Tornos will tell the story of its progression over 100 years, and entrance into multitasking, with the SwissDECO premiere. In line with the premiere of its multitasking machine, Tornos will be manufacturing a multitasking pen. Visitors will walk by machine stations and assemble the final product with each pen part custom made on Tornos machines.

SwissDECO 36

The SwissDECO multitasking single-spindle lathe is suitable in demanding industry segments such as automotive, medical and dental, electronics and aerospace, due to enhanced machining and tooling solutions. The SwissDECO is equipped with optimized programming tools and ergonomics for quicker parts programming and fewer set-ups. Available in multiple configurations and dimensions (25.4 mm bar diameter and 36 mm)-combination turret with B-axis for turning/milling operations, opposing gang and more - the version with a dual gang will be displayed at IMTS. It allows seamless integration of options such as the oil mist extractor, chip conveyor, heat exchanger, fire protection system, high pressure pumps and a bar loader.

MultiSwiss 6x16

Accommodating workpieces up to 16 mm in diameter and 40 mm long, with 14 linear axes and seven C-axes, the MultiSwiss' productivity can be further boosted by the addition of up to three, Y-axes. This MultiSwiss platform is based on an all-in-one concept, which combines the benefits of single-spindle turning machines with the advantages of multi-spindle machines. Highly productive, just one MultiSwiss can replace multiple single-spindle lathes while providing more production capacity, less floor space and it requires fewer operators. "Due to its motorized barrel, these solutions achieve the same production rates as cam-type machines-but with a quieter operation. The machine features a large door opening for front access and integrated peripherals, makes set-ups quick and easy, and the simplified programming makes it simple for single-spindle operators to get great results. The dynamic and entirely independent spindles allow angular positioning and optimal speeds in each position. Since each spindle has its own Z-axis with hydrostatic bearings, flawless finish is achieved and tool life is extended by 30 to 40%," said a company spokesperson.

MultiSwiss 8x26: On Display at Methods Booth

Accommodating workpieces up to 26 mm in diameter and equipped with eight spindles, each position can hold up to four tools. With eight highly dynamic synchronous motor spindles and quick barrel indexing, the new MultiSwiss 8x26 helps users achieve heightened productivity. Its powerful 11-kW motor spindles feature high torque (16.1 Nm) and operate independently to ensure the optimum speed for each operation as well as controlled positioning in frontal and counter operations. Reaching speeds of 8,000 RPM in only a few tenths of a second, these motor spindles make a major contribution to the machine's performance. Optionally, the machine can be equipped with multiple Y-axes to boost its capabilities and allow more tools and full control of the Y-axis for off center holes or any specific milling operation. The machine is available in three configurations: without Y-axis (entry level); with three Y-axes (intermediate); with six Y-axes (complete) for the most complex parts.

SwissNano

The machine's unique kinematics enable turning, drilling, cutting, deburring, roughing and finishing operations, allowing it to produce two-thirds of watch movement components-from the simple to the most complex-and it is equally adept at executing micro medical and dental parts with quality and precision. The SwissNano machine design delivering enhanced balance, and its thermal management allows operating temperature to be reached rapidly to achieve enhanced results. This compact solution offers accessibility for easy set-up, and can be used with a fixed/rotating guide bushing-or no guide bushing at all.

Two SwissNano machines will be displayed: the American flag patriotic decal SwissNano in the Tornos booth in its "history room" under the deck, alongside the 100 year-old No. 20 1917 Swiss lathe. The other SwissNano will be showcased at Methods Machine Tools' booth.

Swiss DT 26: On Display at Methods Booth

The entry level, 25.4 mm single-spindle lathe with five linear axes, is designed to easily withstand heavy-duty machining. "Its wide machining area optimizes chip flow, and its modular tooling zone-unique in this machine range-makes it easy to mount a thread whirling or polygonal milling device. This easy-to-use, flexible workhorse offers a quick return on investment in today's demanding business environment," said the spokesperson.

Swiss GT 26

Simple and ergonomic, the Swiss GT range offers easy access to all tool positions. It is easy to use and maintain due to its automatic lubrication unit, a chip tray and a high volume removable oil pan. Available in three diameters-32 mm for the Swiss GT 32, 25.4 mm for the Swiss GT 26 and 13 mm for the Swiss GT 13-the line is specifically designed to drive successful production of long and short turned parts.

The Swiss GT 26 may be fitted with up to 40 tools, including 14 rotating tools. The Y-axis offers increased machining capability in counter operation and allows some complex workpieces to be produced without reworking. In addition, the B-axis (option) extends the Swiss GT 26's capabilities and features a modular position that can incorporate either a fourth rotating drilling station or a true thread-whirling head.

Esco NM 6 Flexi

The Esco is based on a unique concept in which the material-coil stock or bar-does not rotate. Instead, the cutting tools mounted on the spinning tool head rotate around the material. This concept contributes to high performance and cost savings in the manufacture of small, medium and large lot size parts. With its new design and the use of two completely independent cross tables for the front and back machining units, the NM6 Flexi is flexible and productive. Two parts can be machined at the same time: one in the turning and front machining unit and the other positioned in the counter spindle via back and side operations. The NM6 Flexi features four turning tools on the rotating tool head and a choice of cutting tools or inserts, as well as flexibility of straightening due to the machine's electric drive and programming from the console. Straightening quality is improved through control of the rotational and traverse speed. The machine features simple front access and easy programming using the latest FANUC Oi-TF control technologies.

Tornos No. 20, 1917, Lathe

Tornos' history begins in 1914 with construction of Swiss-type automatic lathes, in today's Moutier, Switzerland plant. The No. 20 machine from 1917, from the Tornos museum in Switzerland, launched the mass production of its successor, Tornos M10, and thereafter the first cam multi-spindle machine, the Tornos AS 14. Since then, Tornos produced the first CNC multi-spindle machine in 1988, CNC 632, and Tornos DECO and MultiDECO machines in 1996 with more than 10,000 of these machines installed globally and running today. "The 2011 launch of the MultiSwiss 6x14 with cross-over concept bridging Swiss-type and multi-spindle lathe technologies and now the launch of the multitasking SwissDECO are truly changing the future of bar turning," said the spokesperson.

Industry 4.0

IMTS visitors will experience TISIS live, with Tornos service engineers analyzing the status of connected machines at IMTS. "TISIS machine communication and programming software is the portal to Industry 4.0 and measuring production efficiencies," said the spokesperson. With TISIS, machine operators get more interactive means of interfacing and intervening to manage unexpected situations. "This smart and advanced ISO code editor puts the user on the fast track to effortless programming and real-time process monitoring - even on a smartphone," said the spokesperson.

TISIS is available in both full and lite versions.

For more information contact:

Tornos US

840 Parkview Blvd.

Lombard, IL 60148

630-812-2040

info-us@tornos.com

www.tornos.us

IMTS 2018 Level 3, Booth S-339053