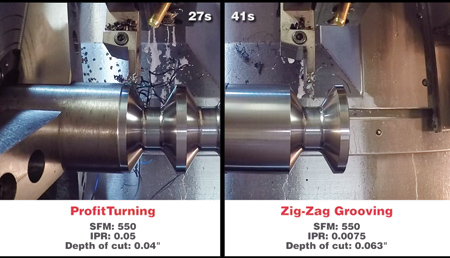

Cycle time reduced from 41 seconds to 22 seconds

"ProfitTurning, released in the latest version of the ESPRIT CAM software, represents years of research," said a company spokesperson. "A lathe roughing strategy that reduces machine cycle time, ProfitTurning has hurdled a grueling series of tests, delivering a performance that promises to take machinists, engineers and industrialists to greater levels of precision, quality control and productivity."

ProfitTurning is a high-speed lathe roughing strategy developed by DP Technology Corp. for O.D./I.D./face cutting and other tasks. It can also extend tool life by minimizing wear. "Compared to conventional ramping methods, ProfitTurning reduces machine cycle time as well as the frequency tooling inserts need to be replaced," said the spokesperson.

DP Technology's R&D Director of Product and Engineering Ivan Kristic said, "ESPRIT 2016's ProfitTurning toolpath maintains consistent cutting forces and chip loads, allowing cutting speeds to be increased. By employing trochoidal turning and controlled engagement techniques, the ProfitTurning toolpath also reduces vibration and residual stresses, which in turn makes it particularly well-suited to thin walls or hard materials, especially super alloys. The net result is reduced cycle times and maximized productivity."

ESPRIT 2016 uses a physics-based cutting engine, which provides the foundation for the technologies such as ProfitTurning.

"While traditional cutting strategies consider only the geometry of materials, ESPRIT 2016 taps deeper into the science of how different industrial materials can be cut in the most efficient ways possible. Its new toolpath technology uses the principles of physics to formulate unique strategies for each cutting challenge," said the spokesperson.

To do that, ESPRIT 2016 inputs all relevant factors in the toolpath algorithm such as tool material, tool shape, workpiece material, tool speed, feedrate, chip deforming, chip load, machine tool power, acceleration and deceleration. This helps establish complete control of the cutting environment, allowing for optimal cutting everywhere along the toolpath.

For more information contact:

Richard Allen

Corporate Marketing & Communications Director

DP Technology

1150 Avenida Acaso

Camarillo, CA 93012

805-388-6000

richard.allen@dptechnology.com

www.dptechnology.com