CLC Horizontal Gear Hobbing Machines

January 1, 2015

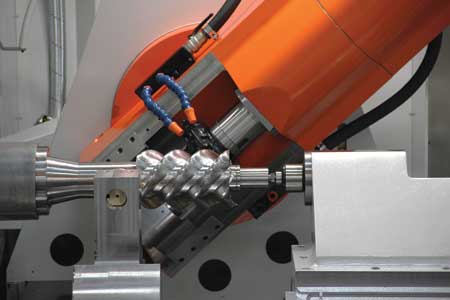

CLC 500-H horizontal gear hobbing machine

CLC 260-H horizontal gear hobbing machine

Koepfer America has introduced the CLC "H" series of heavy-duty horizontal gear hobbing machines to the North American gear manufacturing market. According to the company, these machines offer a competitive and fully customizable solution for high-precision, CNC horizontal gear hobbing.

The CLC 260-H is rated at 7.874" (200 mm) diameter at 4 DP (mn 6.0). Larger workpieces can be hobbed with a maximum swing of 20.472" (520 mm) diameter. The larger CLC 500-H is rated at 19.685" (500 mm) diameter at 0.847 DP (mn 30.0) with a maximum swing diameter of 31.496" (800 mm).

Both machines can be built with different bed lengths to provide axial travel up to 118" (3,000 mm), making either machine a flexible solution for shafts and pinions. The machines feature a large through-hole in the work spindle for extra-long workpieces.

Standard features include high-speed direct-drive torque motors for both the work and cutter spindles, FANUC 31i numeric control and optional skiving (carbide re-hobbing) capability with an integrated electronic timing probe. They are also equipped with a high-speed hob head that swivels +/-45°. For high-helix worms or rotors, a special CLC 500-FR-H form milling machine is available.

"The CLC 'H' series machines can be specially customized as needed to provide customers an optimal solution for their gear manufacturing needs," said a company spokesperson.

For more information contact:

Koepfer America LLC

635 Schneider Drive

South Elgin, IL 60177

847-931-4121

www.koepferamerica.com

< back