Developing his photographic venture during the recent recession, Rob Pleas created these tripod accessories, using GibbsCAM for CNC programming, and his Lagun 717-S for machining components. His first three products, left to right: folding L-bracket; gimbal tripod head to support a camera and long lens for smooth panning; and quick-release balancing clamp for mounting camera or lens on some tripod heads.

To eliminate reflections in the field, Pleas uses flat black anodizing on aluminum components, as shown in the first photographic accessory he created, a gimbal tripod head. Untreated components are shown in the background.

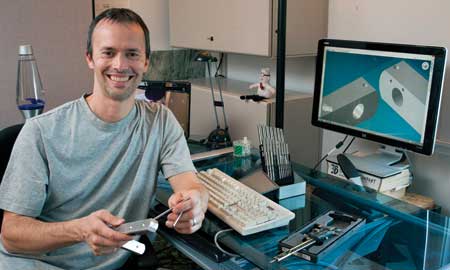

Rob Pleas holds a machined tripod-head bracket, during inspection, displaying solid models of brackets in GibbsCAM, which directly opens product and part designs he creates with SolidWorks.

Pleas completely relies on GibbsCAM in programming his restored Lagun CNC, shown here machining two brackets from aluminum billet. The table provides space for two vises when machining the longer billets for the tripod head.

With assistance from Lagun's service department, Rob Pleas restored his 717-S, enabling him to move production in-house. Here, he sets up workpieces to machine parts for his L-bracket, which enables fast swing-and-lock to change a camera from horizontal to vertical positions.

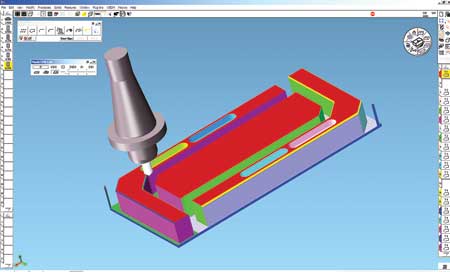

GibbsCAM Cut Part Rendering displays the toolpath and surface finish Rob Pleas will get at the machine after post-processing the toolpath with the GibbsCAM post, developed precisely to take advantage of the control's capabilities. Cut Part Rendering, which can use different colors for tools or operations, here displays two tripod brackets as tool chamfers edges.

When Rob Pleas (pronounced "place") took the initiative to expand his fabrication business into new areas, he soon realized that manual machines would not be able to keep up with increasing production demands. His new product lines also required extensive programming and testing before production could begin. A more efficient, easy to use and cost-effective method was needed.

Pleas originally founded The Welding Place, a 1,600 sq. ft. facility in Puyallup, WA, to make custom ornamental railings, gates and fences. When the economy went into recession in 2008, Pleas' shop survived by providing repair and fabrication services, and also by producing new products, such as a cargo carrier for the Polaris RZR ATV. During this time Pleas also took the opportunity to develop his photography business, a venture that required tripod attachments. The cost of available products was prohibitive and, Pleas joked, he had to adhere to his wife's restrictive "If you can build it, you can't buy it."

Pleas had learned manual machining by watching educational videos, and used his manual lathe and mill to prototype a tripod head. "The market offered high-end professional heads that weighed 3 lbs. or more," said Pleas. "I wanted to create a lighter model for people who did not want the extra weight and expense. My tripod head weighs 1.5 lbs., uses solid aluminum for two L-brackets instead of tubing with good bearings and nice features."

When he had a working prototype, he approached a Seattle photographic store, which suggested changes that Pleas incorporated. The store liked the result, took a few tripod heads on consignment, and soon began carrying them.

Later, at an exposition where photographic vendors, buyers and users congregated to view new products, the Seattle store introduced a customer to Rob Pleas who needed a way to quickly flip his camera between horizontal and vertical positions. Pleas agreed to build an attachment, launching a second product, a folding 5" L-bracket with locking pin, which he has since built in a larger version to accommodate larger cameras.

Pleas quickly realized that working with manual machines was not productive. It took nine hours to machine parts for a complete prototype head, and revisions took nearly as long. For production, he would need a CNC, and with no desire to learn and use G-code programming, he would need CAM software.

In 2012, Pleas sold his manual machines to acquire a used, 1997 Lagun 717-S CNC mill in disrepair. During restoration, Pleas developed a good relationship with Lagun's service department, which he deemed "fantastic." The machine has a 58" x 11" table, XYZ travels of 32", 17" and 7", 16" knee and 40 taper 55-4,250 RPM spindle. Despite the large amount of restoration work required, the machine acquisition was a sound investment.

Pleas then purchased an entry-level CAM system. Although it was almost adequate for programming simple welding supports, it proved to be too problematic, taking hours to program simple parts and yielding programs that nearly always required debugging. When one problem was fixed, another would appear. A program might simulate properly, and then fail at the machine. He could count on losing two to four pieces on a 10-piece run. "I would spend hours, and sometimes days, programming, testing and troubleshooting," Pleas explained. "I lost all confidence in programming and had no confidence in that software. Compounding problems, the CAM and CAD companies blamed each other."

The general purpose CAD system worked well for ornamental weldments and supporting hardware, but it took too much time to make even minor changes, which prototyping frequently requires. A part might take four hours to design, and require three hours of reconstruction just to change a radius. So, in early 2014, Pleas acquired SolidWorks Pro, which provided what he needed for modeling and design iterations. What took four hours previously, he could do in 30 minutes. Minor modifications would take minutes.

In the spring, with success at Seattle stores, Pleas approached B&H Photo, the major international photo-video-audio retailer. B&H was interested. Suddenly, Pleas needed to become "a production guy," instead of a prototyper who outsourced production (and attendant profits). He began looking for CAM software, taking much time over several months to research four brands. "I finally chose GibbsCAM," said Pleas. "Their main competitor would not come here, wanted me to travel to a monthly training session an hour away, and thought I would be wowed by toolpath optimization and buy his software immediately."

The GibbsCAM representative was completely different. "He was all about helping me, on my schedule, and knew I did not want to waste weeks programming or traveling to a presentation that may not answer my questions," Pleas said. "He valued my time, drove two and a half hours to my shop and never pressured me for a sale. Very knowledgeable in machining, he determined my needs and even suggested some improvements. He was there to help. For demonstration, he used one of my parts. The software was like their tag line - 'Powerfully Simple. Simply Powerful.'"

Pleas purchased the software in June, choosing to learn it on his own with GibbsCAM manuals and on-line tutorials and relying on his representative for back-up. "The support from him and from Gibbs was fantastic," he added.

According to Pleas, the software changed everything. GibbsCAM opened SolidWorks files directly, and programming was fast and easy. Time-saving features were readily available. He came to rely on the Profiler feature, which allows taking a cross section of a model, anywhere and in any orientation, and moving it to define a toolpath. "For the tripod head, I machine two Ls at a time," said Pleas. "When I move a cross section of the bracket down a little, I have my toolpath with the click of a mouse. To get the profile around one L, the previous system would take 20 minutes; with GibbsCAM, it takes a minute."

Changes are equally simple and fast, according to Pleas. Changes in the part model automatically update the toolpath. GibbsCAM also has toolpath optimization.

To verify toolpath and check for gouges, Pleas relies on Cut Part Rendering, GibbsCAM's toolpath simulation, which allows verifying single operations or the whole program, at any time during programming or design. His representative said that what he sees on the screen is what he will get on the part, both toolpath and finish. "I did not believe it," said Pleas, "so I tried to make it fail, using various ways to fool the system, but it never failed. Now I rely on it."

Post-processing proved to be as exacting as toolpath simulation. Programs ran exactly as simulated. "Most surprising of all, the machine ran quieter, ran smoother and left a surface finish that I only wondered about before," Pleas added. "With the first program, I could hear the difference. It was like running a different machine. The Gibbs post-processor group worked with me to ensure the post used the control's exact language. It has never failed."

Three months after acquiring GibbsCAM, Pleas was doing his own production, using the single CNC mill and a 1950 Sheldon manual lathe he inherited. He revised the tripod head and modeled the folding L-brackets with SolidWorks, and hopes product demand will enable the addition of a larger CNC mill in the future. Regardless of the complexity of machine tools he may one day need, he knows GibbsCAM can program them. In the meantime, he is working on a fourth photographic accessory, facilitated by the ease of modeling with SolidWorks, and the ease and speed of programming with GibbsCAM.

For more information contact:

The Welding Place

253-548-7176

sales@theweldingplace.com

www.theweldingplace.com

Yvonne Anderson

Gibbs & Associates

323 Science Dr.

Moorpark, CA 93021-2092

805-523-0004

yvonnea@gibbscam.com

www.gibbscam.com