SPC Roberts, SPC Hodge and PFC Adams cutting a part that was built using SigmaNEST software. Photo courtesy U. S. Army - 11th Armored Calvary Regiment.

The 11th Armored Calvary Regiment's new Jet Edge waterjet system is operated by the Service & Recovery Section of the regiment's Maintenance Troop, Regimental Support Squadron (RSS). Pictured from front to rear (l-r): SGT Hardin, SPC Tucker, SPC Barlow, SGT Stanger, CW2(P) Ash, SPC Millbank, SPC Hodge, PFC Adams, SGT Bouknight, SGT Lemberg, SPC Stokes, SPC Roberts, SPC Beauchemin, PFC Sheldon, SGT Rodriguez. Photo courtesy U. S. Army - 11th Armored Calvary Regiment.

SPC Roberts and PFC Adams programming and building a part with SigmaNEST software. Photo courtesy U. S. Army - 11th Armored Calvary Regiment.

PVS-15 spanner wrench. Photo courtesy U. S. Army - 11th Armored Calvary Regiment.

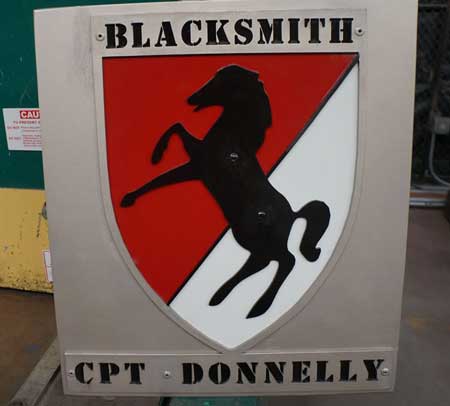

A waterjet cut plaque for departing Soldier(s). Photo courtesy U. S. Army - 11th Armored Calvary Regiment.

The U.S. Army's legendary 11th Armored Calvary Regiment (ACR) has installed a Jet Edge precision waterjet cutting system at its home base in Fort Irwin, CA.

Known for its tough and uncompromising standards, the 11th ACR, "the Blackhorse Regiment," is widely respected as the best Opposing Force in the world. The regiment, which was honored in Tom Clancy's novel "Executive Orders," is responsible for ensuring that the United States continues to have the best trained military in the world by serving as the opposing force in simulated conflicts at the Army's National Training Center (NTC) at Fort Irwin.

The 11th ACR's new Jet Edge Mid Rail Gantry waterjet system is operated by the Service & Recovery Section, a support section within the Regiment's Maintenance Troop, Regimental Support Squadron (RSS). The 20-soldier section is responsible for machining and welding fabricated parts as well as providing recovery support to the Regiment. In addition to its waterjet, the 11th ACR's shop has CNC milling capability, lathes and welding machines.

"We decided to purchase this equipment specifically to assist in expediting our work requests," said Chief Warrant Officer Two Alphonso L. Ash, Jr., who heads the section. "The decision to incorporate the waterjet into our shop operations was based solely on our daily workload as the waterjet has helped to expedite our work requests; the waterjet also allows our section to fabricate parts that have a long shipping date and/or high cost, which has increased our operational readiness."

The waterjet is being used primarily to cut metals ranging from aluminum to armored steel with a thickness from 1/8" to 3", according to CW2(P) Ash. Previously, the soldiers had been cutting these by hand with a plasma torch, oxy-acetylene torches and shear.

"The waterjet is unique because parts can be created using the computer-based software (SigmaNEST) and cut out after the part has been built," said CW2(P) Ash. "Also, the part can be handled immediately following the cut without having concern for heat as in the oxy-acetylene or plasma torch."

Within the first month of installation, the section had already built numerous parts with its Jet Edge including battery shims, transmission shifting linkages, electrical covers, ornamental fixtures and spanner wrenches, said CW2(P) Ash. "I have found that this system has been an excellent and valuable asset to our shop as I have recommended this piece of equipment to many of my peers as part of their shop setup," he said.

"We are truly honored that the 11th ACR chose a Jet Edge waterjet system," said Jet Edge President Jude Lague. "It is humbling to have our equipment selected by the U.S. Army's premier regiment. If you look into their history, it is absolutely amazing because they were involved in so many of the world's historic events during the past 100+ years. We are so proud to be part of their future."

For more information contact:

11th Armored Calvary Regiment

www.irwin.army.mil

Southwest

David Arthur

Jet Edge, Inc.

612-590-5595

sales@jetedge.com

www.jetedge.com

Southeast

AL, FL, GA, MS, NC, SC, TN

David Arthur

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

612-590-5595

sales@jetedge.com

www.jetedge.com

VA

Jeff Schibley

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

765-458-7468

jeffs@jetedge.com

www.jetedge.com

Northeast

CT, ME, MA, NH, NY, RI, VT

Scott Wirtanen

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

800-538-3343

sales@jetedge.com

www.jetedge.com

PA, NJ, MD, DE, NY (metro), Long Island

Automation Solutions, Inc.

2 Hagerty Boulevard, Suite 300

West Chester, PA 19382-7594

610-430-3670

inquire@asi-pa.com

www.asi-pa.com

W. PA

Allegheny Machine Tool Systems Inc.

632 E. McMurray Rd.

McMurray, PA 15317

800-269-4090

724-942-4451

www.allegmach.com

WV

Jeff Schibley

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

765-458-7468

jeffs@jetedge.com

www.jetedge.com

Midwest

KS, MO

David Arthur

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

800-538-3343

sales@jetedge.com

www.jetedge.com

IA, MN, NE, ND, SD, WI

Ben Callahan

Jet Edge, Inc.

612-963-0933

benc@jetedge.com

www.jetedge.com

IL, IN, KY, MI, OH

Jeff Schibley

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

765-458-7468

jeffs@jetedge.com

www.jetedge.com

West

AZ, CA, ID, MT, NV, OR, UT, WA, WY

Brad Schwartz

Jet Edge, Inc.

206-465-6461

baschwartz@msn.com

www.jetedge.com

CO

David Arthur

Jet Edge, Inc.

612-590-5595

sales@jetedge.com

www.jetedge.com