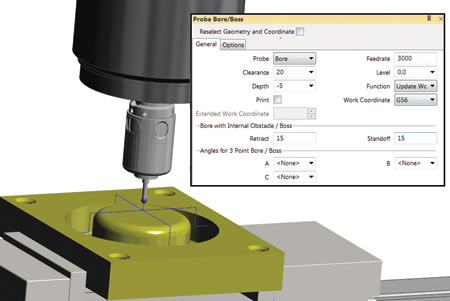

M & H probing

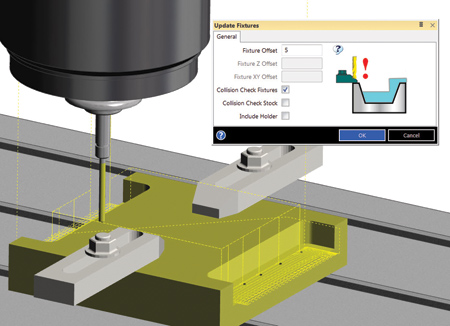

Collision avoidance by checking Link moves between all Milling cycles

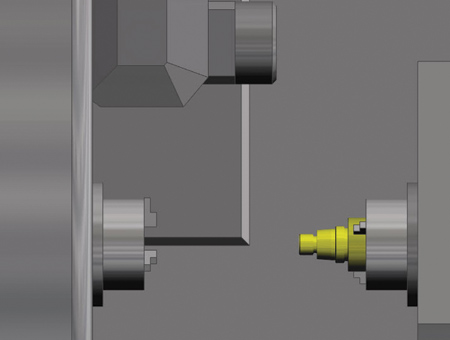

Enhanced Multi-Spindle Lathe Set-Up

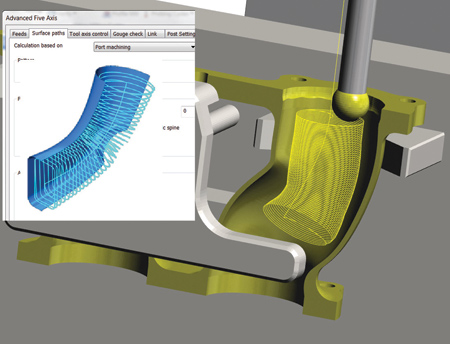

Advanced 5-Axis Port Machining Cycle

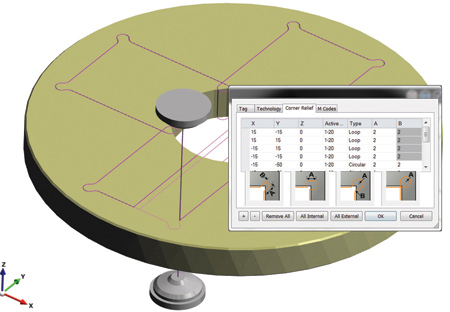

Wire EDM Corner Relief

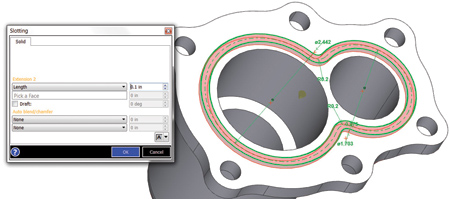

EWS Slot

The latest release of Edgecam's manufacturing software contains a number of new and enhanced CAD and CAM functionality for milling, turning and wire EDM. Highlights include an upgrade to the multi-spindle lathe set-up, a new port machining module for its 5-axis cycle, and time savings through the enhanced hole cycle. Overall, Edgecam 2015 R2 has around 50 items of new and enhanced functionality.

The Lathe Set-Up command has been enhanced, allowing for clearer definition of main and sub-spindle components. This leads to a better understanding of which machining features are active, and means multiple transfers can be made between spindles.

The new Spindle Set-Up command makes it easier to edit the sequence window. Also, the sub-spindle part can be machined away from its home position.

The Advanced 5-Axis Cycle capability has a new Port Machining module, offering both roughing and finishing strategies. The toolpath reaches the full area with a single path, offering two types of cut patterns.

Using the enhanced Hole Cycle in Edgecam 2015 R2 gives significant time savings. Where voids or intersecting holes are detected, the toolpath is automatically adjusted, increasing the feedrate while the tool is not cutting. The NC output is adjusted using the high feedrate of the machine tool.

Enhancements have been made to Edgecam's internal modeling software, Edgecam Workflow Solids (EWS). For the rapid creation of uniform profiles, EWS has introduced a Slotting Tool command, which quickly adopts any profile shape, adding width and depth to the feature. Fillets and corner blends are also supported.

Edgecam 2015 R2 introduces the ability to automatically add dimensional constraints in EWS through the Sketch Analysis command. Users save time when creating sketches extracted from DXF/DWG files.

Wire EDM benefits from further advanced controls for Edgecam's 2- and 4-axis Wire EDM machining cycles. Not only has Corner Relief been added, but the system now offers four variants of the command. For example, where a razor sharp edge is required on external corners, the Loop control is selected. Choosing Circle creates relief on an internal corner.

Since its initial release, the Edgecam Wire EDM cycle has supported interruptions to the wire path in order to introduce Glue Stops, or tags. This command has been enhanced in 2015 R2, automatically producing multiple tags for large, heavy or complex parts.

The latest release delivers additional collision avoidance by checking Link moves between all Milling cycles. Link moves are now automatically checked against Stock and Fixtures, with the tool retracting to a safe height where collisions are detected.

In addition, the items of new and enhanced functionality include support for M & H probing, simulation of screw threads, new machine tool configuration for turning on milling machines, CAD links for Creo Parametric files and support for lathes with sub-spindles offset from centerline.

Edgecam 2015 R2 supports touch probes from M & H. Users can measure workpieces and simulate the probe movements with six individual probing cycles. Each cycle has also been enhanced with eight new functions, giving a wider choice of inspection data.

Machine simulation of thread cutting has been introduced into the new release, allowing users to view and analyze thread forms created by the Thread Turn cycle. It gives a choice of viewing an accurate representation of the thread or a pictorial image.

Enhanced machine tool configuration ensures manufacturers can avoid potential collisions while machining on lathes with main and sub spindles. The sub-spindle locations can be repositioned using the new Offset X Location function. And with the increasing popularity in mill-turn machines, further evolution in Machine Tool configurations means users can now create table-table, head-table and nutated table-table machines, including TNC control.

Finally, with new support for Creo Parametric files, users can now launch Edgecam from within Creo Parametric. The resulting file contains valuable manufacturing information, including thread data.

For more information contact:

Vero USA Inc.

2000 Town Center

Suite 1730

Southfield, MI 48075

248-351-9300

info@verosoftware.com

www.verosoftware.com