Slant Bed Lathe with Box Ways

October 1, 2015

The FBL-360B MC features a low profile and wide front door.

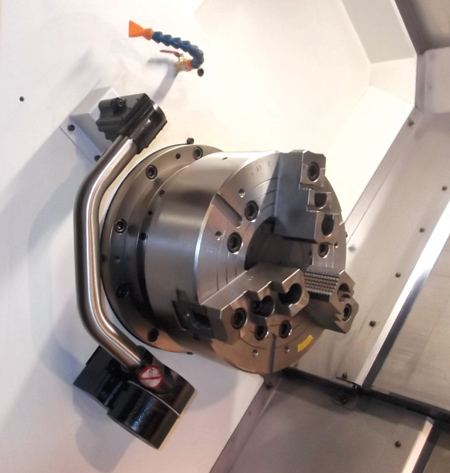

15" 3-jaw hydraulic chuck and tool presetter

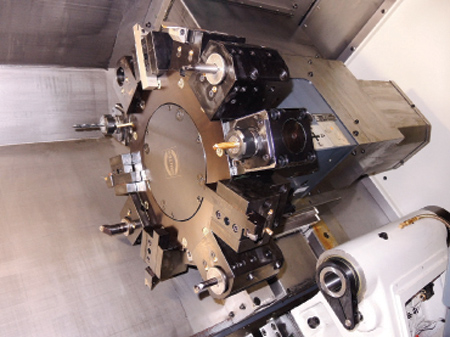

12-station servo turret

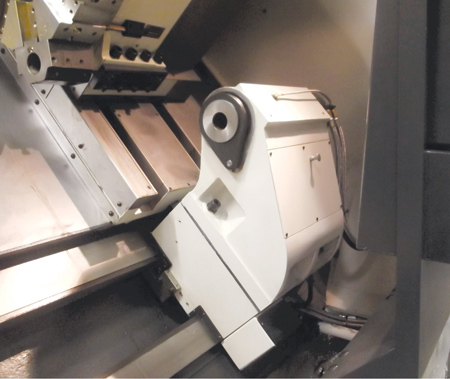

programmable tailstock

Engineered for mixed volume, short-run or dedicated high-volume applications, the newly designed FBL-360B MC from Chevalier features a 45° slant bed, rigid box way structure and programmable tailstock. According to a company spokesperson, the machine is engineered with ease of access and trouble-free maintenance in mind.

Features of the FBL-360B MC:

- Capacity: The FBL-360B MC slant bed lathe features a 15" chuck, maximum swing and maximum turning diameter of 22.4" and a maximum turning length up to 80".

- Structure: The ribbed Meehanite cast iron mono-block casting with rigid box way helps resist deflection and vibration during heavy machining.

The FBL-360B MC provides fast parts machining of bars up to 4.5" in diameter at speeds up to 2,500 RPM, X and Z travels of 12.6" and up to 32.2" and 708 IPM rapid traverse. The X- and Z-axis positioning accuracy is +/-0.0002" while repeatability is +/-0.0001".

- Spindle: The lathe features up to 35 HP (50 HP optional) AC digital spindle motor with 2-speed gear box, spindle bar is 4.5" in diameter and speed up to 2,500 RPM. It produces up to 1,901 ft-lbs. torque at lower RPM and has a 5.3" spindle bore.

- Turret: The German-made Sauter 12-station BMT 65 live turret offers smooth and fast indexing time, while the 15 HP live motor provides large torque to satisfy most milling work.

- Control: The control is a FANUC 0i-TD with 10.4" LCD color screen and conversational Manual Guide i.

- Accessories: Auto tool setter system helps to reduce set-up times and keep non-machining times to a minimum. The programmable tailstock comes with automatic positioning capability, along with a programmable quill that runs IN/OUT sequence.

For more information contact:

Chevalier Machinery Inc.

9925 Tabor Place

Santa Fe Springs, CA 90670

562-903-1929

info@chevalierusa.com

www.chevalierusa.com

< back