Revised production lathe ABC: more speed and flexibility in production

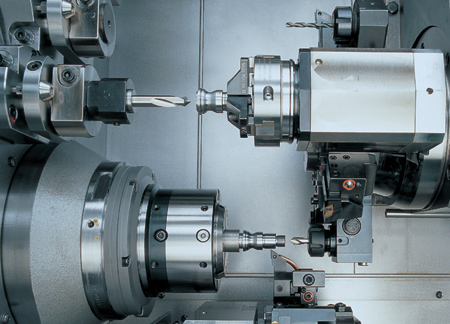

High performance density: up to three tools can be used simultaneously on a small footprint.

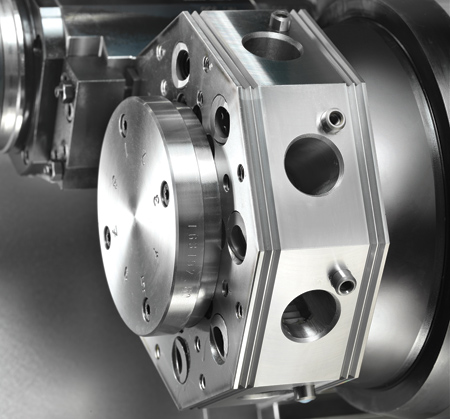

Besides the traditional VDI25 toolholders, the upper turret now can accommodate W-serrated holders. One station is reserved for the synchronous spindle.

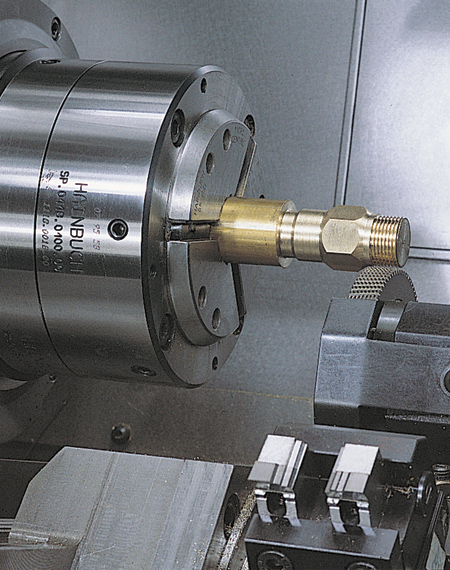

The thread milling and polygon turning unit produces hexagon bar in a fraction of a second.

The lathe features future-oriented operation using the INDEX C200 sl control generation based on the Siemens Sinumerik 840D sl (solution line) and has an 18.5" touch-sensitive wide-screen monitor. The latest capacitive touch technology allows even an operation with gloves. In addition, the control panel can also be used for Virtual Machine (VM) developed by INDEX.

The INDEX CNC lathe ABC revision has retained the essential features of its predecessor but is significantly more productive with performance-enhancing modifications - especially on the drive and control side. The lathe has two tool turrets, of which the upper carries the synchronous spindle for rear end machining.

Main Spindle with 65 mm Bar Capacity

A major modification of the new ABC was made to the main spindle. It has a bar capacity of up to 65 mm and is driven by a synchronous motor instead of the previous asynchronous motor. This makes it more efficient and faster. Its maximum speed is 6,000 RPM, providing 27 kW of power (40% DC) and 145 Nm of torque (40% DC). Air cooling has been retained, since the switch to liquid cooling would have required an additional cooler and thus more space.

Upward Compatibility for Toolholders

The developers also thought about existing ABC users in terms of tool carriers and toolholder systems. As a result, their arrangement in the work area and the equipment of the tool carriers are the same. Only the possibilities of the upper turret have been extended: besides the traditional VDI25 toolholders, it can now also accommodate W-serrated holders. Developed by INDEX, these tool mountings enable high change accuracy during set-up and are frequently used for angled tools (e.g., drills).

The user now has the choice of using the W-serrated mountings supplied with the new machine. But there is no need to do away with the existing VDI toolholders, because they can still be used on upper turret. INDEX has also retained the dovetail mountings in the lower turret. This allows the user to use even tooling systems that come from the ABC's predecessors, the INDEX cam-controlled machines.

Three Tools Engaged Simultaneously

The upper turret - equipped with a tool drive (max. speed 6,000 RPM, power 4.3 kW; torque 7.5 Nm at 25% DC) and accommodating seven tools as well as a synchronous spindle - is used mainly for I.D. machining. The lower turret with its six stations is mainly used for O.D. machining. All tool stations in both turrets can thus accommodate live tools. There is a practical innovation in this respect as well: while the lower tool carrier was limited previously to a maximum of 4,500 RPM, this limitation has been lifted in the new ABC and the performance has been raised to a maximum speed of 6,000 RPM (power 3.8 kW, torque 7.5 Nm at 25% DC) - the same as on the upper turret.

The synchronous spindle in the upper tool carrier (max. speed 4,500 RPM, power 5 kW and torque 10 Nm at 25% DC) allows machining of workpieces completely from the back with up to five available back-boring stations.

Two of these back-boring stations can have a separate tool drive with up to 6,000 RPM, 4.1 kW of power and 6.5 Nm of torque (at 25% DC).

Simultaneous centric machining of workpieces with the upper turret on the main spindle as well as one of the three stations of the back-boring unit with the synchronous spindle is possible at the same feedrate on the main and synchronous spindles.

In addition, the lower turret can be used at the same time on the main spindle, so that workpieces can be machined synchronously and productively with up to three tools.

Options

The INDEX ABC production lathe is equipped with a gantry-type removal unit with which the finished parts can be removed gently during main time from the synchronous or main spindle towards the right out of the machine. Bar remnants can be discharged from the main spindle in this way using a separate tray.

The use of the INDEX LMI loading magazine, suitable for bar stock up to 3.2 m length, saves valuable time. The storage tray of the bar support is approximately 300 mm, allowing it to accommodate up to six D50 bars.

Furthermore, a thread milling and polygon turning unit are available with a separate drive (6,000 RPM, 5 kW power at 25% DC). This INDEX development is particularly vibration-absorbing, because the power is transmitted via a toothed belt. Also the polygon turning tool head made of heavy metal provides largely vibration-free running through its high inertia. A company spokesperson stated that this allows a hexagon bar to be produced with high-quality surfaces in a fraction of a second, even in steel, for which cutters would need much more time.

Easy to Use and Process-Reliable

Like all newly developed INDEX machines, the ABC will also be equipped with the INDEX C200 sl control generation, which is based on the Siemens Sinumerik 840D sl (solution line) and an 18.5" touch-sensitive wide-screen monitor. The control panel concept developed by INDEX reduces the complexity in using the control by integrating numerous rotary and tip switches on the machine control panel directly on the touchscreen.

The operating panel can, however, do more than just operate the machine. It features a second input, which INDEX uses for its Virtual Machine (VM) option. On the push of a button, the operator can switch to the "VM on Board," for example, to use the simulation independently from the running machine operation. The VM, which can be run purely with CNC code, works with a VPC box installed in the control cabinet that offers many additional possibilities.

Other VM features developed by INDEX include CrashStop and RealTime. CrashStop allows the advanced simulation of workpiece programs on the machine. RealTime allows the simulation of the machine program simultaneously on the control panel, providing a real-time view of the machining sequence.

Another new feature is the openness for information technology through the XPanel operating concept, which is included as standard. The machine operator can also use the control panel to obtain information from the corporate network, such as component drawings to set up the machine.

Cost Reduction Through Full-Featured Packages

For more than a year, INDEX has provided the ABC also as full-featured package solutions, which offers the machine and includes selected equipment features and options.

The advantage of this package idea is better planning of production, as well as quantity effects, which reduce cost.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

www.indextraub.com

Southwest

N. TX

G.B. Newbury Machine Sales

6301 Windhaven Parkway #314

Plano, TX 75093

214-914-8869

newburymachine@yahoo.com

OK

Gage Machine Tool

10668 Widmer Rd.

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

Southeast

AL, GA

Applied Machine Solutions, Inc.

2200 Airport Industrial Dr., Suite 300

Ball Ground, GA 30107

678-880-0893

info@appliedmachine.com

www.appliedmachine.com

NC, SC, VA

Advance Machinery Sales, Inc.

416-C Gallimore Dairy Rd.

Greensboro, NC 27409

336-665-9114

FL

MIT (Magna Innovative Technologies)

18 South Brooksville Ave.

Brooksville, FL 34601

352-799-2211

sales@mitcnc.com

www.mitcnc.com

Northeast

DE, MD, E. PA, NJ, NYC, Long Island

Automation Solutions, Inc.

2 Hagerty Blvd., Ste. 300

West Chester, PA 19382

610-430-3670

inquire@asi-pa.com

www.asi-pa.com

N. NY

Britton Machinery Sales

330 Castlebar Rd.

Rochester, NY 14610

585-924-9335

www.brittonmachinery.com

W. PA

Marcus Machinery

106 Bellefield Court

Gibsonia, PA 15044

412-862-0803

info@marcusmachinery.com

www.marcusmachinery.com

MA, CT, RI, ME, NH, VT

Northeast CNC, LLC

36 Bartlett Rd., Unit 1

Gorham, ME 04038

207-775-5510

sales@necnc.com

www.necnc.com

Midwest

KS, W. MO

Gage Machine Tool

10668 Widmer Rd.

Lenexa, KS 66215

913-894-1233

www.gagemachinetool.com

WI (except w. counties)

Iverson & Company

441 North 3rd Ave.

Des Plaines, IL 60016

847-299-2461

sales@iversonandco.com

www.iversonandco.com

MI

Methods & Equipment Associates

31731 Glendale Ave.

Livonia, MI 48150

734-293-0660

sales@methods-equipment.com

www.methods-equipment.com

MN, IA, ND, SD, NE (eastern counties), WI (western counties)

Hales Machine Tool, Inc.

2730 Niagara Lane North

Plymouth, MN 55447

763-553-1711

sales@halesmachinetool.com

www.halesmachinetool.com

West

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street E.

Fife, WA 98424

253-926-6868

sales@ellismachinery.com

www.ellismachinery.com