The VM 9 spindle down turning center offers flexible production for small batches of chucked components.

Work area of the VM 9 with a bottle spindle to hold workpieces up to 450 mm.

The VL series for highly productive manufacturing: Idle times on these machines have been reduced to an absolute minimum. For example, the chip-to-chip time on the VL 2 is just 5 seconds.

The parts are transported by an integrated automation system and loaded and unloaded using the pick-up principle.

At SOUTH-TEC 2015, October 27-29 at the Charlotte Convention Center, EMAG will feature manufacturing systems for precision metal components with the North American premier of its new VM spindle down machine platform for the low-cost production of small batches and complex geometries.

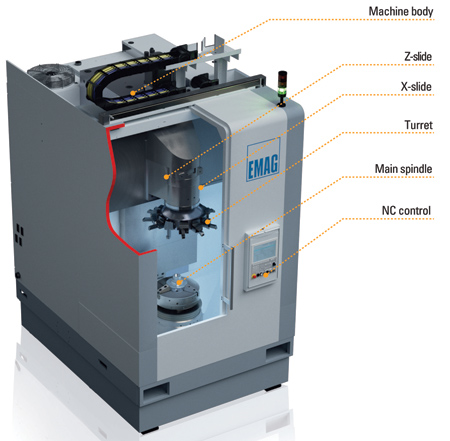

"Part of the large family of EMAG modular machines, the VM 9 vertical turning center combines a reliable platform with an extensive range of equipment. Designed to machine chucked components with a maximum diameter up to 450 mm, it features a tool turret which can be fitted with up to 12 tool positions and can be equipped with driven tools to carry out drilling or milling operations. An integrated probe delivers absolute process reliability by ensuring continuous quality control of the workpieces, making the VM 9 extremely well equipped for a wide variety of production tasks, enabling it to produce a wide range of workpiece formats," said a company spokesperson. The VMC MT series expands the machine concept with a focus on universality so it can be configured to suit almost any customer request. Complete machining using a wide variety of technologies is a key feature and the VMC MT series offers a standard tool magazine with 40 positions, expandable to 120 tooling options. Various spindles complement this range to make the VMC MT series the all-round solution for a wide variety of workpieces.

The VL series will also be on display for visitors to experience the EMAG modular inverted vertical lathe design. With the aim to develop a system of modular machines ideal for use in the manufacturing of medium and large batch runs, one common feature of all four machine sizes is the shared modular, compact design. Its small footprint means reduced floor space costs and flexibility in machine layout. Every VL machine features an integrated automation system for transporting workpieces. "When combined with the self-loading pick-up spindles, this automation concept ensures short cycle times and high productivity. To accommodate machine operators, all the service units are easily within reach, with the various units (electrics, hydraulics, cooling system, cooling lubricant and central lubrication system) accessible at any time so that the machines can be maintained with ease," said a company spokesperson.

"The technologies in the EMAG Group cover the entire spectrum of metalworking, including non-traditional processes," said an EMAG spokesperson. "Electro-Chemical Machining (ECM) is used in the aerospace sector for the manufacture of blisks, while laser welding is essential in lightweighting automotive components. eldec modular induction (MIND) hardening systems are now also available, the latest addition to the technology portfolio. Featuring Simultaneous Dual Frequency (SDF) technology, eldec hardening systems complement the workpieces machined by EMAG lathes to create efficient, complete production lines. The flexible machine concepts and complete systems from EMAG offer modular and customized solutions for the production of workpieces in nearly every industry."

For more information contact:

Peter Loetzner

EMAG LLC

38800 Grand River Ave.

Farmington Hills, MI 48335

248-477-7440

info@usa.emag.com

www.emag.com

SOUTH-TEC 2015 Booth 1331