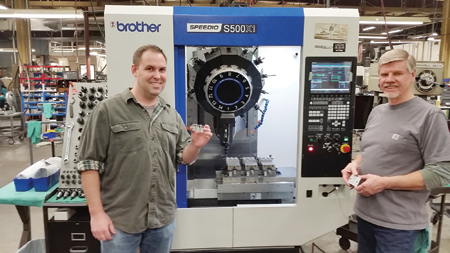

(l-r) Valco Melton Manufacturing Engineering Manager Eric Frey and CNC Machinist Dan Inderrieden with the Brother Speedio S500X1.

With the new Brother Speedio machine, Valco Melton can use its previous tooling while cranking up the spindle speed and feedrates.

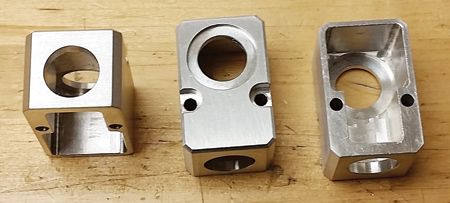

Pocketing operations for three components were reduced from 27 minutes to under eight minutes, all while achieving better and more consistent surface finishes.

Brother Speedio S500X1 high-speed VMC

Valco Melton's headquarters in Cincinnati, OH

Valco Melton of Cincinnati, OH, is a global producer of automated adhesive application equipment for the packaging industry across the worldwide market. With expanding market potential, the company sought to improve its throughput. The company hoped that replacing outdated machining centers would help it to produce equipment components faster and more accurately. It also wanted to minimize changeovers from one part program to another, and capitalize on a library of current part programs that periodically repeat in the shop.

Valco Melton was using a 3-axis vertical machining center (VMC) installed in 1996. This machine was inconsistent in creating parts to required print tolerances, and Valco experienced wide variations in part finishes. Some parts require deep pocket milling, profiling, drilling and tapping operations. Valco Melton's average cycle time for these parts was in excess of 27 minutes, with part tolerances at times exceeding the allowable +/- .005". In order to produce consistent part appearances to satisfy customer requirements, the company had to slow axis feedrates significantly, particularly on deep pocket milling operations.

Yamazen recommended the Brother Speedio S500X1 high-speed VMC with the new CNC C-00 control to machine Valco's 6061 T6 aluminum connector blocks.

The new CNC C-00 control features improved axis acceleration rates and improved surfacing and contouring capability. The full color 10.4" display monitor adds to the operator's ease in using this machine.

The Speedio machine was delivered and installed by Yamazen's Cincinnati Technical Center. The CNC machine operators were shown a convenient way to convert the existing part programs into the new Speedio CNC C-00 control. "This was the easiest machine startup and training we have ever had," said Valco Melton Manufacturing Engineering Manager Eric Frey.

"The new Brother Speedio S500X1 has better rigidity than competitive 30 taper machines on the market," continued Frey. "Another reason for our selection is the ease of programming it features both G-code capability and conversational programming."

Valco Melton's CNC machinist Dan Inderrieden was particularly pleased with the layout of the new CNC-C00 control and the ease of programming. Inderrieden stated that he "has learned a lot on this machine" and enjoys the brightness of the 10.4" color control display.

With the new Brother Speedio machine, Valco was able to use the same tooling, but crank up the spindle speed and feedrates and achieve a cycle time of under eight minutes, all while achieving better and more consistent surface finishes on the critical deep pocket milling operations.

Typical component material machined at Valco Melton includes aluminum billet, D2 tool steel, 300 and 400 grade stainless and some brass.

The Brother Speedio S500X1 features a 10,000 RPM spindle with 1.4 sec chip to chip and a 15% increase in Z-axis rigidity over the previous model.

"This machine exceeded our cycle time targets we set in our capital justification - resulting in a faster return on investment than we estimated," said Frey.

Valco Melton specializes in adhesive dispensing machinery, vision inspection and electronic monitoring systems for quality assurance.

"Our goal is to continue to bring innovative solutions to market and partner with manufacturers to help them achieve their cost and productivity goals," said Frey.

For more information contact:

Eric Frey

Manufacturing Engineering Manager

Valco Melton

411 Circle Freeway Dr.

Cincinnati, OH 45246

513-874-6550 Ext. 208

eric.frey@valcomelton.com

www.valcomelton.com

Yamazen Inc.

735 E. Remington Road

Schaumburg, IL 60173

800-882-8558 / 847-882-8800

www.yamazen.com