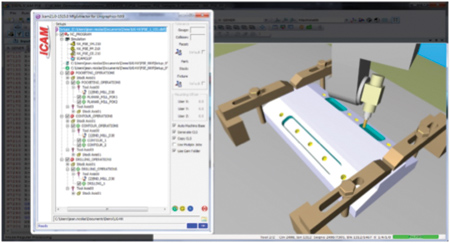

ICAM's interface inside NX CAM

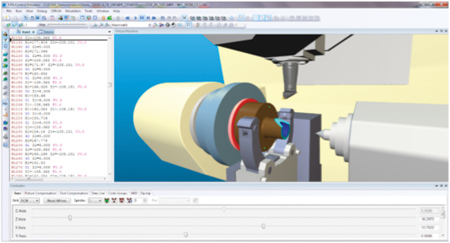

Adaptive Post-Processing for mill/turn applications

ICAM Technologies Corp. and Siemens have signed a PLM Solution Partner Program Agreement allowing Siemens to extend and enhance its product suite.

Under the terms of this agreement, ICAM has developed a complete graphical user interface to NX CAM and its database, allowing for the full integration of ICAM's Adaptive Post-Processing solution within NX CAM. Doing this now provides a familiar and efficient environment for NC programmers to concurrently post-process, optimize toolpath and verify G-code, all within NX CAM and in one simple process.

Adaptive Post-Processing is new technology developed by ICAM that changes traditional CNC programming methodology by creating a unique integrated environment for the traditional independent steps of post-processing, toolpath optimization and G-code simulation. This new methodology allows all of these steps to be executed simultaneously, permitting cross communication among them and allowing for automatic toolpath corrections with a single click execution.

This integrated solution allows for the in-process evaluation of feedback from the post-processor, machining simulator and ICAM's other toolpath optimization technologies to automatically create an optimized NC program for a target CNC machine. This all occurs in one process, allowing NX users to automatically and efficiently reduce both NC programming time and machining cycle times.

"The iterative steps of the traditional serial method of toolpath creation, post-processing, machine simulation and G-code verification most often generate errors, leaving the tedious investigative work as to where the errors occurred in the hands of the NC programmer," said a company spokesperson. "ICAM's Adaptive Post-Processing solution not only eliminates these errors while reducing programming time, but also allows the programmer to adopt ICAM's philosophy to create toolpaths for the part as opposed to the traditional method of programming the part for the machine while worrying about its kinematics and collisions. Creating toolpaths while using Adaptive Post-Processing also eliminates the reprogramming of the part for a new target CNC machine."

"Siemens PLM Software is enthusiastic about the collaboration with ICAM. This agreement is the first step in the development of an integrated solution that will provide added value to our mutual customers," said Steven Hard, Software & Technology Partnerships, Siemens PLM Software.

"Under the Siemens PLM Solution Partner Program, ICAM is excited to have its best-in-class technologies fully integrated within NX CAM and accessible by the Siemens customers and sales channels," said John Nassr, President of ICAM Technologies."

For more information contact:

ICAM Technologies Corporation

21500 Nassr Street,

Sainte-Anne-de-Bellevue, Qubec,

Canada, H9X 4C1

800-827-ICAM / 514-697-8033

info@icam.com

www.icam.com

Siemens PLM Software

info.plm@siemens.com

www.plm.automation.siemens.com