"The machines in the VMC MT series, designed to be highly flexible production centers, focus on universality and can be configured to suit almost any customer request," said a company spokesperson.

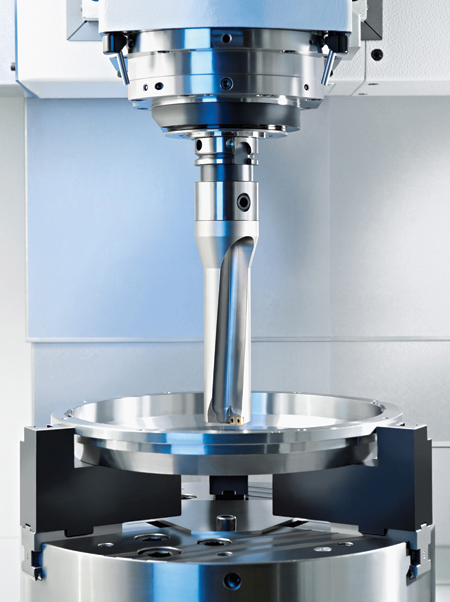

"The main aim of the VMC MT series is complete machining using a very wide range of technology," said a company spokesperson. "There are various tool magazines for the machines with up to 200 available tool positions, and various spindle options complement that range."

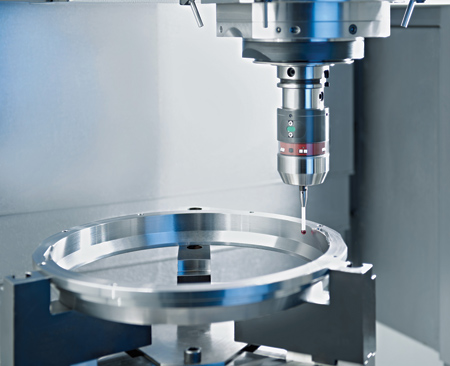

The laser measuring bridge outside the machining area monitors the wear and diameter of the tools and is designed to ensure that the machining process is uninterrupted.

A radio probe, which is available as an interchangeable system, monitors the quality of the workpieces.

The machines in the VMC MT series are suitable production systems for chucked parts with complex geometries. "Whether they are used for prototype production or for fast changes in small production runs, the VMC MT series from EMAG is designed to meet the demands of flexible production situations due to the ergonomic accessibility of the machining area and the bottom-mounted workpiece spindle," said a company spokesperson.

Offering several equipment options, the basic design of the VMC 300 MT, VMC 450 MT and VMC 600 MT remains the same. "The machine base is made of Mineralit polymer concrete featuring good damping properties," said the spokesperson. "The turning/milling spindle is mounted on a compound slide with X- and Z-axes to produce excellent, fast machining results. The workpiece itself is clamped on one of the three bottom-mounted spindles available - 49, 83 or 138 / kW - each tailored to the machining job suiting the customer's demands. Due to the designed accessibility to the machining area, workpieces can be easily loaded by hand, using a crane or, alternatively, the machines can be connected to robots or gantry loaders using an NC-controlled loading hatch on the side. This maintains excellent access to the workpiece and clamping chuck.

"Universality is the main feature of the VMC MT series. For example, not only is the whole range of turning, drilling and milling technologies available, but the turning/milling spindle is also available in two versions, with a rating of either 26.4 kW or 43 kW. However, the use of a tool magazine allows the most complex geometries to be achieved with a wide variety of parts, enhancing productivity. Various magazines with up to 200 tool positions can be selected. The wide choice of tools is also beneficial to retooling times, and the overall equipment effectiveness (OEE) can be increased by up to 30% as a result. Only the clamping method must be tailored to the workpiece; the tool buffer is fitted with an adequate number of tools at all times. The operating condition of each tool is ensured by a laser measuring bridge outside the machining area that checks the wear, the diameter of the tools and the tip distance to base of turning tools to ensure perfect production results every time. An interchangeable radio probe can be used to check workpiece quality."

The VMC MT series also offers enhanced ergonomics. "The machining area and all maintenance components are easy to access, demonstrating that the design of the machine was centered on small production runs with a wide range of workpieces and on prototype production," said the spokesperson. "These tailored working conditions also enhance productivity.

"With the VMC MT series, EMAG offers a new machine system for chucked parts suited for the production of complex workpieces in many different manufacturing scenarios due to its flexibility. The VMC MT series is suitable for use in applications such as the aircraft industry, trucks, construction or agricultural machinery. The machines offer flexible adaptability for chucked parts and frequently changing component families."

The spokesperson also reported the following benefits of the VMC MT series:

- Highly dynamic axes for short idle times and quick machining processes

- Axis monitoring by rotary, indirect absolute encoders; all axes with fully encapsulated linear glass scale (optional)

- Generously dimensioned main spindle, maintenance-free spindle motors and rigid guideways

- Machine base made of Mineralit offers six to eight times better damping properties than gray cast iron.

The spokesperson also provided the following technical data for the VMC MT series:

- VMC 300 MT

- Chuck diameter: 315 mm

- Maximum weight: 300 kg

- Swing diameter over base: 500 mm

- Maximum turning diameter: 300 mm

- X-axis/Z-axis travel: 735/500 mm

- Main spindle: flange size 8; bearing 140/160 mm

- Main drive unit: synchronous motor (40% duty cycle) 49/83/138 kW; torque (40% duty cycle) 585/990/1,650 Nm; maximum speed 3,000/2,400/2,000 RPM

- Feed drive: rapid-traverse rate X/Z 60/30 m/min; feed pressure in X/Z 4/8 kN

- Motorized milling spindle: synchronous motor (25% duty cycle) 26.4/43 kW; torque (25% duty cycle) 120/196 Nm; maximum speed 12,000/7,000 RPM

- VMC 450 MT

- Chuck diameter: 450 mm

- Maximum weight: 300 kg

- Swing diameter over base: 650 mm

- Maximum turning diameter: 450 mm

- X-axis/Z-axis travel: 500/500 mm

- Main spindle: flange size 8; bearing 140/160 mm

- Main drive unit: synchronous motor (40% duty cycle) 49/83/138 kW; torque (40% duty cycle) 585/990/1,650 Nm; maximum speed 3,000/2,400/2,000 RPM

- Feed drive: rapid-traverse rate X/Z 60/30 m/min; feed pressure in X/Z 4/8 kN

- Motorized milling spindle: synchronous motor (25% duty cycle) 26.4/43 kW; torque (25% duty cycle) 120/196 Nm; maximum speed 12,000/7,000 RPM

- VMC 600 MT

- Chuck diameter: 630 mm

- Maximum weight: 500 kg

- Swing diameter over base: 800 mm

- Maximum turning diameter: 600 mm

- X-axis/Z-axis travel: 650/580 mm

- Main spindle: flange size 11; bearing 190 mm

- Main drive unit: synchronous motor (40% duty cycle) 138/150 kW; torque (40% duty cycle) 585/990/1,650 Nm; maximum speed 2,000/1,500 RPM

- Feed drive: rapid-traverse rate X/Z 60/30 m/min; feed pressure in X/Z 12/20 kN

- Motorized milling spindle: synchronous motor (25% duty cycle) 38/56 kW; torque (25% duty cycle) 256/384 Nm; maximum speed 5,500 RPM.

More information about the VM and VMC series may be found at http://vm-vmc.emag.com/es/.

For more information contact:

Peter Loetzner

EMAG LLC

38800 Grand River Ave.

Farmington Hills, MI 48335

248-477-7440

info@usa.emag.com

www.emag.com

Southwest

AR

David Fitzgerald

EMAG LLC

Charlotte, NC

248-595-1117

dfitzgerald@emag.com

www.emag.com

NM

Peter Loetzner

EMAG LLC

38800 Grand River Ave.

Farmington Hills, MI 48335

248-442-6590

info@usa.emag.com

www.emag.com

LA, OK, TX

Ric Lorilla

EMAG LLC

Houston, TX

248-595-1530

rlorilla@emag.com

www.emag.com

Southeast

AL, FL, GA, MS, NC, SC, TN, VA

David Fitzgerald

EMAG LLC

Charlotte, NC

248-595-1117

dfitzgerald@emag.com

www.emag.com

Northeast

NY, PA

James Petiprin

EMAG LLC

38800 Grand River Ave.

Farmington Hills, MI 48335

248-910-8413

jpetiprin@emag.com

www.emag.com

CT, DE, MA, MD, ME, NH, NJ, RI, VT

Jonathan Chomicz

EMAG LLC

Hartford, CT

248-497-8526

jchomicz@emag.com

www.emag.com

WV

David Fitzgerald

EMAG LLC

Charlotte, NC

248-595-1117

dfitzgerald@emag.com

www.emag.com

Midwest

MI, OH

James Petiprin

EMAG LLC

38800 Grand River Ave.

Farmington Hills, MI 48335

248-910-8413

jpetiprin@emag.com

www.emag.com

IL, IN, WI

Tod Petrik

EMAG LLC

Chicago, IL

248-470-2646

tpetrik@emag.com

www.emag.com

IA, KS, MN, MO, NE, ND, SD

Bill Konetski

EMAG LLC

Minneapolis, MN

612-804-0857

bkonetski@emag.com

www.emag.com

KY

David Fitzgerald

EMAG LLC

Charlotte, NC

248-595-1117

dfitzgerald@emag.com

www.emag.com

West

AZ, CA, CO, ID, MT, NV, OR, UT, WA, WY

Peter Loetzner

EMAG LLC

38800 Grand River Ave.

Farmington Hills, MI 48335

248-442-6590

info@usa.emag.com

www.emag.com