Turning head holders have been added to the range of machining accessories supported by FeatureCAM.

Delcam's 2015 R3 FeatureCAM feature-based CAM software includes a range of enhancements to give high-quality results on all types of machine tools, including complex mill-turn equipment and 5-axis machining centers, while retaining rapid programming times.

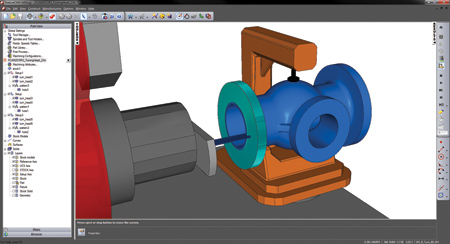

The most significant new option is the ability to duplicate the physical constraints of the machine tool in simulations in FeatureCAM. Machine tool limits can be added to the models to be used in the simulation for 3-, 4- and 5-axis milling machines, for turning equipment and for mill-turn machines, including those with multiple turrets and/or multiple spindles. It is then possible to check that the chosen machine tool is capable of completing the proposed program for all types of equipment, from the simplest lathe to the most complex multi-tasking machine.

The simulation will pause whenever the program attempts to move the machine beyond the specified limits. In many cases, simply changing the position of the part on the machine bed will allow the whole operation to be completed. Alternatively, modifications to the fixturing or to the length of the cutting tools may be required. Whenever changes are made, the computer simulation can then be repeated to check that the modified program will run successfully. Proving out the program on the computer will save time and money on the machine tool, as well as checking that the part can be cut safely.

In another improvement to FeatureCAM simulations, more accurate representations can be created of shanks and holders. These allow 3-axis and 5-axis collision checking to be undertaken more reliably.

Two enhancements have been made to 5-axis machining with FeatureCAM. Firstly, more control is available with the ability to set the C-axis orientation about the Z-axis, so helping to avoid machine collisions and to make the program more efficient by avoiding over-travel. Secondly, support for 5-axis operation is possible in 2D spiral operations, giving better control of the tool axis. This can ensure uniform depth of cut and cross-section when engraving onto complex surfaces, including parts with undercuts.

Additional accessories that are supported in the new release include turning head holders and mini turrets. Turning head holders allow turning to be undertaken on a milling machine, while mini turrets allow more flexible positioning of the tooling and faster tool changes. In both cases, the new options can be simulated on the computer before being sent to the machine.

For more information contact:

Delcam

877-335-2261

marketing@delcam.com

www.delcam.com