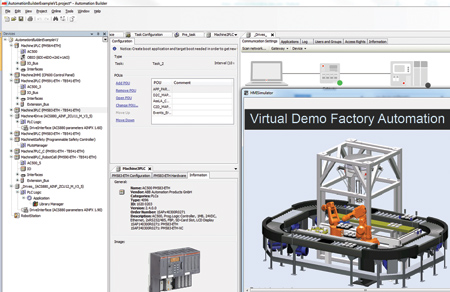

ABB's Automation Builder integrated development environment for automation components

"ABB's Automation Builder reduces software complexity and cuts time to market and cost of ownership," said an ABB spokesperson.

The new release of ABB's integrated development tool suite is designed to enhance the speed and efficiency of industrial control and machinery automation projects.

"Automation Builder 1.1 provides an integrated development environment for solutions using the spectrum of automation components - including PLCs and safety PLCs, motion controllers, drives, robots and HMIs to reduce software complexity, time to market and cost of ownership," said a company spokesperson.

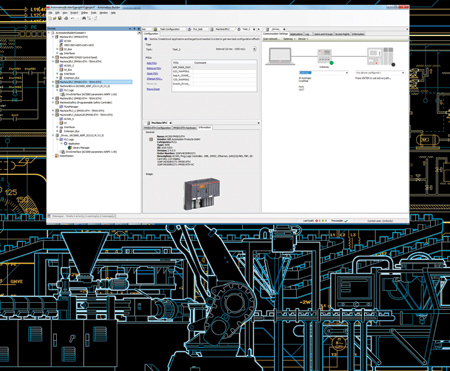

The latest release of ABB's software extends the data exchange capabilities with electrical planning and engineering software with a new bi-directional interface to the widely used EPLAN Electric P8. Electrical automation and PLC design data may be imported, modified and transferred back to the electrical CAD environment - eliminating any need to manually enter data and thereby ensuring synchronization of signal identification between the two software environments.

The release now includes a comparison function that allows engineers to see what might have changed since they last looked at a project, and provides the ability to use profiles of previous development tool versions for compatibility.

Support for new hardware includes: the ability to program the latest member of the AC500 PLC family, the PM595 CPU; programming ACS880 IEC61131-3 programmable drives and the DCT 880 thyristor power controller; and developing motion control systems with ABB's new MotiFlex e180 servo drives or the ACS580 general-purpose drive.

Another important new element of the software is the introduction of an easy-to-use download and licensing system. ABB offers three licensing options: a basic version suitable for first time PLC users and engineers working on smaller-scale automation, motion and drive projects (this is available at no cost); a standard version that supports integrated engineering of advanced and complex systems, including the use of safety PLCs; and a premium version.

The premium version incorporates C/C+ programming tools, E-CAD interfaces and other high level features for optimal productivity, easy collaboration and simpler management of engineering data on large-scale projects involving thousands of I/O points.

With Automation Builder 1.1, users may also automatically update the suite of software tools to the latest versions using a one-click mechanism. A single license covers all of the included software packages.

ABB has also introduced usability improvements to further enhance the user's productivity. These include simplified drop-down menus, drag-and-drop features on the object tree, an improved device repository with search and filter functions, a list editor for AC500 I/O mapping and a re-worked help system.

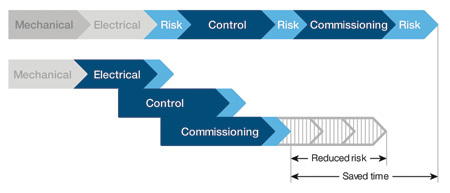

"Software development is the most expensive element of the majority of automation projects," said the spokesperson. "By providing a unified development environment for the complete scope of automation projects, ABB is helping application experts, software and hardware engineers to focus their time and effort purely on developing the application, and not waste time on the myriad of interfacing issues that can arise when building solutions using many different types of automation devices. ABB estimates that the Automation Builder environment can reduce development engineering efforts by around 30% for medium complexity projects, and deliver even higher savings on large-scale projects. This is particularly the case for projects involving many different types of automation components."

Automation Builder provides enhanced PLC development resources in the form of the standards-compliant IEC 61131-3 development environment and ABB's Panel Builder tool for creating HMIs. The software suite also includes tools for configuring and programming the latest generation of ABB's safety PLCs - the AC500-S family - the RobotStudio tool for simulating and programming ABB robot applications and the Mint WorkBench tool with its pre-built and tested libraries for programming ABB's servo drives.

"Software complexity is the number one project issue today for most automation OEMs and system integrators," said Armin Wallnhoefer of ABB. "Automation Builder gives automation developers and owners the means to simplify control engineering and standardize on a single development platform for all projects, regardless of scale."

Users can download a trial version of Automation Builder at www.abb.com/automationbuilder.

For more information contact:

ABB Inc.

1425 North Discovery Parkway

Wauwatosa, WI 53226

800-435-7365

plc.sales@de.abb.com

www.abb.com/plc