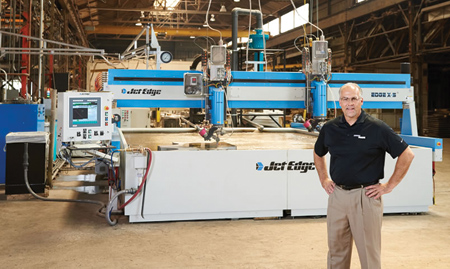

Dan Chatterton, CEO of JACQUET Midwest, with his new Jet Edge EDGE X-5 5-axis waterjet.

(l-r) Ian Mykytka, JACQUET Midwest CAD Engineer and Randy Griffin, JACQUET Midwest Plant Manager discuss their next waterjet cutting project.

Ian Mykytka, JACQUET Midwest CAD Engineer, operating the Jet Edge EDGE X-5 5-axis waterjet.

(l-r) Dan Chatterton, CEO of JACQUET Midwest and Ian Mykytka, JACQUET Midwest CAD Engineer, inspecting a part off the waterjet. The part demonstrates the chamfering and beveling capabilities of the Jet Edge EDGE X-5 5-axis waterjet system.

Jet Edge Inc. announced that JACQUET Midwest has installed a dual head 5-axis Jet Edge EDGE X-5 waterjet cutting system at its metal processing facility in Racine, WI.

The EDGE X-5 is JACQUET Midwest's third Jet Edge system and JACQUET's 13th Jet Edge waterjet nationwide. JACQUET plans to use the new system to provide beveling and chamfering services to its customers in the Midwest as well as nationwide through its five regional service centers.

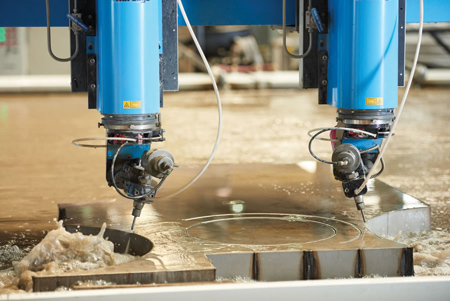

The waterjet system features a 21' x 13' work envelope which enables the metal service center to process full 8' x 20' or 10' x 20' plates. Its dual 5-axis cutting heads double the company's production and is capable of cutting precise 3D parts from virtually any material, including bevels up to 50°. Powered by a 60,000 PSI 100 HP Jet Edge iP60-100 intensifier pump, the ball-screw driven waterjet system is designed for repeatability at +/-.001". The system also has submerged or above-water cutting capabilities as well as a proprietary plate mapping feature that allows precise nozzle-to-plate standoff.

"We are really excited to bring the Jet Edge dual head 5-axis waterjet into our facility," said Dan Chatterton, JACQUET Midwest CEO. "With the precision that we will be able to achieve with the 5-axis taper control machine, we can provide a tighter tolerance part from the top edge to the bottom edge of the part, eliminating a lot of the machining. It allows us to do much more for our customers; we can bevel cut, taper control and chamfer holes on both the top and bottom edges of the material."

Chatterton noted that JACQUET has always equipped its service centers with large gantries to better serve its customers. "When JACQUET decided to add a 5-axis system, we distinguished our company even further by offering the rare capability of dual 5-axis cutting services."

"All of the machines in the JACQUET system are large table machines because of the large plate sizes that we buy mill direct allowing us to be more efficient with our cuts, have longer run cuts and have better nesting," he said. "Our dual 5-axis system is going to provide an even higher level of service to our customers, allowing them to look to JACQUET for all of their cutting needs."

A subsidiary of JACQUET Mid Atlantic, which is a subsidiary of Jacquet Metals of Lyon Saint Priest, France, JACQUET Midwest is one of five JACQUET metal service centers in the United States. The company also has service centers in Pottstown, PA; Carson, CA; Pineville, NC; and Houston, TX. JACQUET recently acquired the Rolark Group service centers in Canada, with subsidiaries in Edmonton, Toronto and Montreal.

JACQUET specializes in supplying and processing stainless steel and nickel alloys for OEMS, fabricators and machine shops that support primarily the oil and gas, power generation, pollution control systems and water purification industries. JACQUET's North American service centers provide waterjet and plasma part cutting. The company stocks 19 different grades of stainless steel and nickel alloy plates in a wide variety of sizes and thicknesses.

For more information contact:

JACQUET Midwest

262-898-1381 / 877-202-8911

www.myjacquet.com/Midwest

For more information about Jet Edge contact:

IA, MN, NE, ND, SD, WI

Ben Callahan

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

612-963-0933

sales@jetedge.com

www.jetedge.com

MI, IL, IN, OH, KY

Jeff Schibley

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

765-458-7468

sales@jetedge.com

www.jetedge.com

KS, MO

David Arthur

Jet Edge, Inc.

12070 43rd St. NE

St. Michael, MN 55376

612-590-5595

sales@jetedge.com

www.jetedge.com