GibbsCAM 2016 reads native format SOLIDWORKS 2017 part models and assemblies.

3D Systems has announced that its suite of GibbsCAM 2016 software for programming CNC machine tools has been certified by DS SolidWorks for its SOLIDWORKS 2017 mechanical CAD software. This certification assures that engineers and CNC programmers can use GibbsCAM 2016 to program simple and complex parts for machining on all kinds of CNC lathes, mills, turning centers, multi-axis machining centers and multitasking machines, directly from SOLIDWORKS CAD models.

GibbsCAM 2016 is certified for SOLIDWORKS 2017 as part of the SOLIDWORKS Partner Product Program, under which GibbsCAM has been a Certified CAM Product for many years. DS SolidWorks created the CAM certification to identify best-in-class CAM solutions with enhanced interoperability, assuring users that their solution can read the native SOLIDWORKS file format. GibbsCAM 2016 is immediately compatible with SOLIDWORKS 2017 per the requirements of the certification.

"Certification also demonstrates a commitment to joint SOLIDWORKS-GibbsCAM customers, and ensures these customers can take advantage of the latest GibbsCAM enhancements to achieve the highest productivity from SOLIDWORKS 2017," said a spokesperson. "In combination with GibbsCAM automation features, integration with SOLIDWORKS simplifies preparation for machining and makes machining much faster, saving huge blocks of time for SOLIDWORKS-GibbsCAM users. GibbsCAM's short learning curve and unique, shop-friendly user interface provide additional productivity from ease of use, reliability and speed of programming."

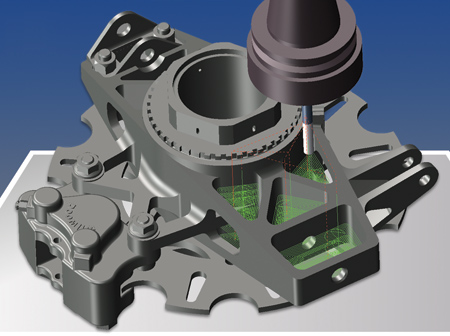

GibbsCAM directly reads SOLIDWORKS part models and assemblies, preserving features and attributes such as holes and color, and uses these characteristics to identify, organize and select features for machining. Alternatively, with the GibbsCAM SOLIDWORKS add-in, SOLIDWORKS users can transfer files directly into GibbsCAM on the same workstation with the "Transfer to GibbsCAM" menu option. GibbsCAM's optimization for SOLIDWORKS includes integration of the GibbsCAM Hole Manager with SOLIDWORKS' Hole Wizard to identify, categorize and machine simple and compound holes. This allows GibbsCAM's Automatic Feature Recognition and Feature Manager to read and preserve features from the SOLIDWORKS Feature Tree to easily identify and select areas for machining. Whether parts have plain geometry needing only simple milling or turning, or complex geometry requiring use of 5-axis machining, multitask machining or Swiss-style turning, the combination of GibbsCAM 2016 and SOLIDWORKS 2017 covers the entire design-through-manufacturing cycle in production machining across multiple industries.

For more information contact:

3D Systems Corporation

333 Three D Systems Circle

Rock Hill, SC 29730

803-326-3900

moreinfo@3dsystems.com

www.3dsystems.com

www.gibbsCAM.com