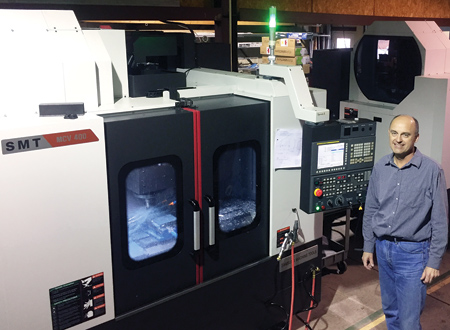

Stephen Kusek, President, HiTek Services

HiTek Services' most recent challenge has been to reduce prices in order to gain an edge over its competitors while still maintaining its high quality. "Our largest customers have become extremely price conscience and have motivated us to work toward replacing older equipment with high-quality machines that do not break the bank," said HiTek President Stephen Kusek.

Additionally, HiTek's existing customer base is anticipating growth, while HiTek is pushing to expand beyond its traditional customer base. The company needed to add capability that would allow it to support other industries that may have more difficult machining needs.

The HiTek team selected as its solution Samsung MCV 400 vertical machining centers (VMCs). "The primary reasons for this selection include the robust design, competitive price and our familiarity with the FANUC control," said Kusek. "We purchased the machines from McDaniel Machinery because of its over 25 year reputation of sales and service to its customers."

"The Samsungs are rock-solid machines," continued Kusek. "The speed, surface finish and accuracy are all as good or better than our other mills."

Most of HiTek's work is done in aluminum and plastic. Kusek said the Samsung's heavy-duty design gives them a better chance to support other industries using harder-to-machine materials, such as stainless steel, Inconel and other more exotic metals.

Features of the Samsung MCV 400:

- 12,000 RPM spindle max. speed

- 15 HP continuous

- 30 tool magazine

- 30" x 17" x 20" travels (XYZ)

- CAT 40 (BIG PLUS) spindle taper

- Chip conveyor

- Coolant through spindle

- Renishaw probe.

So far, HiTek has used the Samsungs to machine aluminum electronics enclosures. "We have been able to push the tools harder and keep a beautiful surface finish," said Kusek. "Our cycle time has been reduced and the overall quality of the part maintained."

HiTek provides customers with a variety of capabilities, including designing, prototyping and manufacturing new products; machining build-to-print components for OEMs; stuffing printed circuit boards at the prototype or production level; and more. HiTek has milling capacities to 50" x 20" and turning capabilities to an 8" diameter.

Owners Stephen Kusek and Michael Caraway are both former engineers from McDonnell Douglas Aerospace in Huntsville, AL (now part of Boeing). They started HiTek to develop and manufacture products for the energy, agriculture, printing and medical industries.

HiTek provides four primary services:

- Engineering

- Machine shop services

- Printed circuit board assembly services

- Electro-mechanical assembly.

HiTek offerings include mechanical, electrical and software engineering; milling and turning built-to-print; and the ability to assemble printed circuit boards (PCBs) or complete products from prototyping through production.

"Our company goals include growing the company at a rate that allows us to continue to provide our customers with the high-quality parts or service they have come to expect from us," said Kusek.

For more information contact:

Stephen Kusek, President

HiTek Services, Inc.

7234 Hwy. 431 South

Owens Cross Roads, AL 35763

256-539-0380

kusek@hitek-services.com

www.hitek-services.com

Samsung Machine Tools America

a Division of Dynamic Intl.

N25W23287 Paul Road

Pewaukee, WI 53072

262-521-1100

www.samsungmachinetools.com

SOUTHEAST

AL, FL (Panhandle), GA, MS, TN

Jim McDaniel

McDaniel Machinery

187 Cahaba Valley Parkway

Pelham, AL 35124

205-403-9900

jim@mcdanielmachinery.com

www.mcdanielmachinery.com