3D Systems to Demonstrate the Latest GibbsCAM Release at EASTEC

May 1, 2017

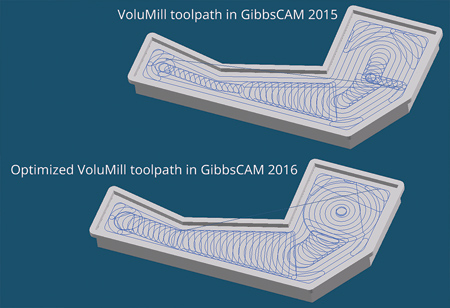

Toolpath shows GibbsCAM's optimized VoluMill technology that can reduce cutting time and tool wear by up to 60%.

3D Systems announced that it will showcase the latest version of its GibbsCAM CNC programming software at EASTEC in booth 5537.

The latest version of GibbsCAM MTM (Multi-Task Machining) software combines flexibility and control in a single, shop-friendly interface together with improvements in milling and turning functionality, 5-axis milling and multi-axis turning. GibbsCAM also features a library of over 1,800 post-processors to support the growing variety of standard and Swiss-style MTMs from nearly 100 manufacturers.

The optimized VoluMill for GibbsCAM wireframe and solids has a new, integrated Technology Expert that calculates the most efficient speeds and feeds for VoluMill toolpaths, and automatically calculates spiral toolpaths in large pockets. Open face milling calculations reduce cutting time by up to 60% while optimized cutting motions in slots and corners further reduce cutting time and tool wear.

The 5-axis milling has been improved and now includes:

- Flowline, a new pattern type that creates U or V aligned toolpaths on a single surface without selecting additional bounding geometry.

- A new Mirror Toolpath function available for Surface, Triangle Mesh, Swarf Machining and Wireframe strategies.

- A new Follow Surface Topology functionality that allows for stripe milling, which follows the actual curvature of the surfaces in Swarf Machining when using multiple slices.

- A new Gouge strategy that avoids collisions by retracting along a plane normal to the tool axis while retaining tool orientation and height.

For more information contact:

3D Systems Corporation

333 Three D Systems Circle

Rock Hill, SC 29730

800-654-9399

gibbscam.info@3dsystems.com

www.3dsystems.com

EASTEC Booth 5537

< back