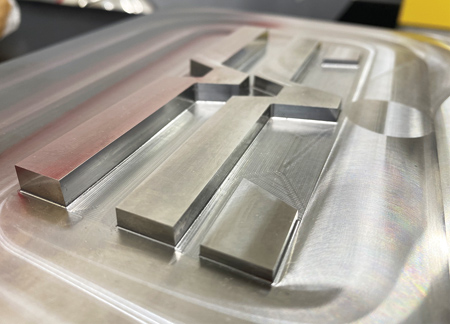

Hard milling for moldmaking: STAVAX 52HRC on YASDA YBM950V, 50 mm to 55 mm thickness

Methods Machine Tools, Inc. has released five tips for improving moldmaking return on investment.

1. How can I evolve my moldmaking processes to reduce my reliance on EDM and secondary operations?

Hard milling, combined with high speed machining, opens new opportunities to increase your production rates and achieve higher quality. New moldmaking processes, including factory and turn-key automation, can reduce the burden on operators and reduce manual intervention. That means operators do not touch the part more than necessary, resulting in a higher quality part coming off the machine.

2. How can I introduce automation into my moldmaking?

The best machines are capable of running long periods of time-days, nights, weekends-as long as they are properly tooled and maintenanced. Shops can gain the ability to move components in and out of the machine without operator intervention.

Automation takes many forms, but it does not mean only robotics. In many cases, an automated pallet system embedded in one machine and to linked another, including inspection machines, can deliver the desired infeed/outfeed system to achieve new process efficiencies.

3. How can I make the financial case for introducing automation into my business?

The discussion should begin by analyzing your cost per employee-a key business performance metric-including labor rates and hours of operations-and devising a strategy to raise that revenue per employee.

As your revenue grows in tandem with the number of hours your shop operates, your operating costs will decrease. If your first shift has 10 people, second has five and a third shift goes down another 25%, the operating costs of those two latter shifts have lowered the total cost of operation.

The question is, how do you get and achieve the same amount of output in those areas without having the operators involved? This goes back to key processes that you created, including palletization, automation, a highly-efficient, high-quality machine you run parts through at any time and/or through the weekend.

4. How do I position my business for success?

Many OEMs are looking for molds to sustain 3 million hits. That is a significant increase from when fewer than one million hits satisfied. Higher demands require superior technology to deliver the expected quality in the least amount of time.

Secondly, drive investment for better machining centers and automation. What worked in the past is not a recipe for future success. Today's mold market demands businesses continue to evaluate, learn and adapt as needed to stay competitive and position themselves for growth.

The speed of change in today's machining technology creates an imperative for shops to keep pace. If shops are not current on the latest processes and technology, the pitfalls will be external on the market and internal with team members who desire working with the best solutions. Netted out, without a strategic investment plan and overall company vision, companies will be left behind.

Identify the strengths and weaknesses of your business, and most importantly, the opportunities where you can mature your business over the long haul. Business owners should always evaluate new opportunities that tap into existing strengths, and present lanes for investment.

5. Lead with confidence

The moldmaking market has endured peaks and valleys in recent years, but confidence in the industry remains strong, especially as OEMs continue to pursue reshoring their suppliers.

According to Grandview Research, the U.S. moldmaking market is expected to grow by 4% compound annual growth rate (CAGR) by 2030, led by increased demand in the medical, automotive and consumables markets.

As industry technology continues to evolve, do not hesitate. When matching a sound business strategy with robust technology (including automation), shops have an opportunity to demonstrate significant capabilities and win more contracts.

For more information contact:

Methods Machine Tools, Inc.

65 Union Avenue

Sudbury, MA 01776

877-MMT-4CNC (877-668-4262)

www.methodsmachine.com

SOUTHWEST

William Keim

General Manager-TX, LA

Methods Machine Tools

wkeim@methodsmachine.com

SOUTHEAST

David Chesnutt

General Manager-Southeast

Methods Machine Tools

dchesnutt@methodsmachine.com

NORTHEAST

Brad Catyb

General Manager-New England

Methods Machine Tools

bcatyb@methodsmachine.com

MIDWEST

Kevin Fite

General Manager-MI/OH

Methods Machine Tools

kfite@methodsmachine.com

Mike James

General Manager-IL/WI

Methods Machine Tools

mjames@methodsmachne.com

WEST

Kevin Lichtenberg

General Manager-Rocky Mountain States

Methods Machine Tools

klichtenberg@methodsmachine.com

Dan Pierce

General Manager-CA, OR, WA

Methods Machine Tools

dpierce@methodsmachine.com