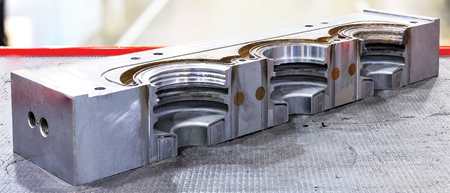

The additive process enables the use of mixed materials and incorporate harder, wear-resistant materials to increase the life of the repaired mold.

Photo: Oak Ridge National Laboratory.

Hybrid manufacturing combines additive technologies and traditional subtractive machining in the same working space. This process continues to expand into mainstream manufacturing. The ability to leverage additive and subtractive methodologies produces a synergistic approach to manufacturing that necessitates a reevaluation of product development processes from design to production.

OPEN MIND Technologies, developers of the hyperMILL CAD/CAM software suite, offers integrated, comprehensive additive and hybrid CAM strategies. The hyperMILL programming environment enables CAD functions, additive functions and subtractive tool path strategies that can be performed and simulated within the same system. This holistic workflow offers clear advantages over a segmented approach that depends on multiple software choices that may not integrate seamlessly.

For example, mold repair is required after repeated cycles due to various wear processes. "Mold repair by additive/hybrid techniques is more cost effective than wholesale replacement of entire molds," said a company spokesperson. "Not only can selected features be repaired with additive manufacturing, the additive process enables the use of mixed materials and incorporate harder, wear-resistant materials to increase the life of the repaired mold. Repair with hybrid processes on CNC machines also provides higher quality than is achievable with manual repair processes."

The hybrid manufacturing process using hyperMILL CAM software is an excellent choice to alternative techniques, the company reported. In a use case for the thread repair of a bottle mold, start to finish, all operations were performed on a single Okuma MU8000 Laser EX machine, which is located at the Oak Ridge National Laboratory (Knoxville, TN). The first process step was to machine out the existing threads. The matching material was then deposited using a Directed Energy Deposition laser powder system. Lastly, the form and threads were machined back into the mold.

For more information contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Ave., Unit 3

Needham, MA 02492

888-516-1232

info.americas@openmind-tech.com

www.openmind-tech.com