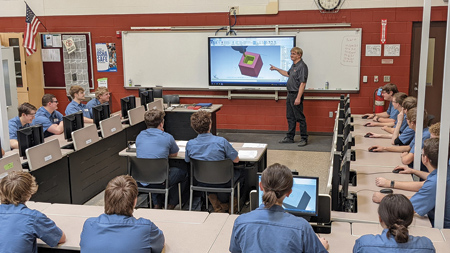

Larry Ray, Instructor in the Precision Machining program at Vantage Career Center, Van Wert, OH, teaches Mastercam CAD/CAM software to his class.

Larry Ray, Vantage Career Center Precision Machining Instructor, reviews Mastercam program with senior Taylor Lucas.

Precision Machining student Allen Minck uses Mastercam CAD/CAM software to program toolpaths.

Vantage Career Center's 2022 Precision Machining junior and senior class with Instructor Larry Ray.

Precision Machining student Kevin Polman sets up a part for machining.

Precision Machining students Allen Minck and Zane Wertenberger set up a part.

2022 Vantage Precision Machining graduate and Ohio State SkillsUSA 1st Place Champion, National SkillsUSA qualifier, Taylor Lucas (Paulding Exempted Village Schools).

In his own words, the school where Larry Ray teaches precision machining is in the middle of nowhere. But manufacturers from all over the region know exactly where Vantage Career Center is.

"We are in a very rural area," said Ray, Instructor, Precision Machining program. "But I still have 20 companies a year contact me, interested in working with us or with the students."

Sometimes the companies need help with a part, and sometimes they are recruiting. Both types of calls underscore the need for skilled labor in the workforce. As the job market continues to heat up, companies have even begun visiting the Vantage Career Center to recruit graduating students.

"We have always had the big guys call us. Like automakers from Detroit," said Ray. "But now we get recruiting calls from shops of all sizes."

These manufacturers know Vantage students have the education and skills they need to hit the ground running as new employees. The school works directly with the state of Ohio to set its curriculum, following both Ohio high school education standards and Ohio Apprenticeship Program standards. High school juniors and seniors in the program spend half of the day in the classroom, learning the core curriculum needed to graduate from high school. The other half is spent in labs, learning everything required to graduate as an apprentice machinist, including manual and CNC machining, manufacturing-specific math and CAD/CAM programming. Upon graduation, they have earned their high school diploma and their apprentice certificates, as well as their OSHA 10 safety certification.

Juniors start at the very beginning with manual machining to get acclimated to the machining environment. "For many of these kids, this is their first exposure to manufacturing," said Ray. "Sometimes the first step is learning the difference between a mill and a lathe."

Seniors get started down the CNC path by learning manual programming and G-code. Learning G-code gives them a skill to lean on if they need it. "You never know what kind of software and machines you are going to have in a shop," said Ray. "Knowing how to write your own G-code may come in handy someday."

During the following semester, students are introduced to CAD/CAM programming. "I start with CAD using Mastercam (CNC Software, LLC, Tolland, CT)," said Ray. He starts with prints that he has already programmed so students can compare their work to an already finished program to help them learn how the software functions.

It is interesting to note here that the school uses Mastercam software in lieu of a separate drafting program. "Since Mastercam Design is included in our suite, we use it for modeling," said Ray.

Mastercam Design is a computer-aided design (CAD) solution that simplifies the creation of even the most complex parts with a robust suite of CAD tools. Users can create models from scratch or import models from other programs. A few years ago, the team from Mastercam Reseller, FASTech, Inc. (Findlay, OH) suggested the addition based on the trends they were seeing with their customers.

"They told us that almost everyone is using CAD/CAM for drafting these days," said Ray.

FASTech regularly works with the school to ensure it has the latest Mastercam software and that instructors are fully trained. Every time Vantage Career Center upgrades, the reseller is there to help.

Students move quickly from 2D drawing to 3D rendering to creating toolpaths under Ray's guidance. When he shows them how to verify their work using Verify and Backplot, the students become excited about being able to create and edit their toolpaths. The Mastercam Verify and Backplot modules let users see the entire machining process exactly how they have programmed it, allowing them to find and correct errors and collisions before parts are machined.

In addition to being able to draw, design and toolpath, students also appreciate the software's flexible programming environment. Each student sets up a programming environment, moving modules around workspaces as needed.

"I tell them that there are thousands of ways to approach programming the same part," said Ray. "You see that idea come to life when you see how different every one of their screens are."

Ray has several practice projects baked into his curriculum to teach students how to use the machines and software. One of the things he likes to do is take a few of the students' versions of the projects they have designed and machine them. The class then compares chip removal, machine speed and part accuracy.

"We do that using a Dynamic toolpath first," said Ray. "Then we run the parts on a machine so they see how accurate Mastercam is from the screen to the machine. I spend a lot of time comparing the speed and efficiency of each part. I do that to teach students that how they approach a part matters. It makes them better machinists."

In addition to the projects and parts Ray assigns from their curriculum, the students often hone their skills on part requests the school gets from local communities and companies. One such project was a part of Vantage's community engagement initiative. Seniors from the Precision Machining, Industrial Mechanics and Carpentry schools joined forces to create railings for an elevated walking path in a nearby community. They worked with a local Lion's club, which organized the project.

"We get a lot of requests like that," said Ray. "We also get a lot of specialty and one-off parts that the shops around here do not have time for."

One such example is an auto body shop that remade a Volkswagen Beetle into a branded car for a local beverage distributor. The "Coca-Cola Car" needed several specialty parts, including bottle-shaped bumpers and the specialty brackets to attach them to the vehicle.

"The students used Mastercam to design the bumpers and create all the toolpaths to machine it in 5-axis," said Ray. "I helped them if they asked, but they did almost all of it themselves."

They also frequently help a local company that works on transmissions and has had a hard time finding shops that can make specialty spacers and other parts for them.

The students who show exceptional proficiency or passion for their work are asked to join the school's SkillsUSA Championships team. The SkillsUSA Championships are career competition events showcasing the best career and technical education students in the nation. Contests begin locally and continue through the state and national levels.

Vantage students compete against other schools in the region in categories including CNC machining, CNC lathe programming, CNC milling and CNC technology (programming machines). Precision Machining teachers help the team hone their machining skills, while FASTech provides additional programming training to give them the experience and knowledge they need to move on to higher levels of competition.

The extra work pays off, as Vantage usually has at least one teammate move on to the state level competition. A few years ago, it even had a team win on the national level. Whether they are on the SkillsUSA team or not, by the end of their senior year, all students bring everything they have learned together as they plan and execute their senior projects.

"They choose whatever they want," said Ray. "I make sure their projects are doable on the machines we have in school, and then I get out of their way."

Every senior conceives, designs and machines the project by themselves. They can use any machine in the shop, including the waterjet and 5-axis machines. Ray recounted some of the projects that his students have turned in, including a working grandfather clock machined from aluminum. One student designed and manufactured lighter parts for the midget car he raced as a hobby.

The students use Mastercam from the beginning of their projects to the end, including determining which machines to use, tolerances for each part, how to machine the parts and testing the finished product to make sure everything works as intended. While they have completed several parts and projects during their coursework, many times this is the first time they have had to think about how the parts will eventually come together into a working product.

"When they start creating their toolpaths and verifying them in Machine Simulation, I see the light come on," said Ray. "They stop thinking about each part as its own thing and start thinking about their entire assembly."

Mastercam Machine Simulation gives users the ability to prove out toolpaths for 3-, 4- and 5-axis machining operations. Users can detect collisions, text filtering scenarios and test tool cutters before sending final code to the machine.

One student, for example, created salt and pepper shakers. She was verifying her design in Mastercam and realized the parts were not threaded correctly, so they would not screw together and work properly.

"Other CAD/CAM software could not do that," said Ray. "You cannot design, draft and verify at the same time the way you can with Mastercam."

The student was able to rework her design to fix the problem before programing the machine, saving herself from poorly machined parts, a bad grade and a lot of spilled salt.

For more information contact:

CNC Software, Inc.

671 Old Post Road

Tolland, CT 06084

800-228-2877

info@mastercam.com

www.mastercam.com

Vantage Career Center

818 N Franklin St.

Van Wert, OH 45891

419-238-5411

www.vantagecareercenter.com