EMCO founder Karl Maier (center) with his first employees (left) and a demonstration vehicle (right).

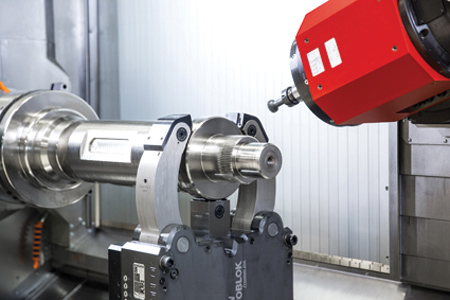

The universal UMILL 1500 machining center and the flexible Hyperturn 200 turning and milling center at EMCO's Technology Centre in Wendlingen, Germany.

"Combined machines such as the HYPERTURN 100 Powermill reflect the successful merger of the best of both machining worlds implemented jointly by developers from different EMCO locations," said a company spokesperson.

In 1947 engineer Karl Maier established a small workshop where he built lathes. In close dialogue with potential customers, he first developed small lathes and then expanded his product range to include hardness testing machines.

By the end of the 1970s, his son Ernst Alexander took over the company which, after growing steadily until the early 1990s, became an established manufacturer of additional machines and equipment. Heavily hit at that time by the economic crisis, the machine builder was taken over by an international industrial holding company that shifted the focus into core competencies in the areas of conventional and CNC machine tools for production and training purposes. Close cooperation with customers and the adjustment of the development focus are still at the center of the corporate strategy.

"Developed at that time to allow for highly productive complete machining, the EMCO TURN 332 and the EMCO TURN 465 were the first multichannel machine tools equipped with two tool systems and two turning spindles," said a company spokesperson. "Now firmly established in the market, EMCO continues to experience positive development. With the takeover of the FAMUP and MECOF companies in 2004 and 2011, the way towards becoming a turn-key provider for machining operations had been paved. The upward trend was further boosted in 2011 when the EMCO Group was taken over by the Salzburg-based Kuhn Holding. Employing around 800 people at five production sites, EMCO has become one of Europe's leading machine tool manufacturers."

The company continuously invests in its locations-most recently with the allocation of over $1 million for the expansion of EMCO Famup, the production facility in San Quirino, Italy.

While the company offers sophisticated turning and milling centers that come in a wide range of designs, it is also focused on providing training machines equipped with state-of-the-art control technology and various types of courseware.

"For 40 years, young people have worked with training machines to become familiar with the realm of machining and the world of EMCO machines. Training organizations use them as frequently as vocational schools or technical colleges and universities. This is where technophiles get to know the advantages of our technology, which is something they will appreciate later on," explained Managing Director Stefan Hansch.

A straightforward introduction into the operation and programming of CNC machines is provided by EMCO's user-friendly training machines. The control unit, running on an industrial PC, emulates the models of the major CNC providers, including Siemens, FANUC and Heidenhain. Trainees and teachers alike are thus able to learn how to handle all common user interfaces.

"A solution provider focusing on the productivity of the entire machining process, EMCO has succeeded in strengthening its position as a turn-key provider," said Hansch. "This is based, in particular, on the effective merger of all competencies. The success of this strategy is reflected in many areas. The longstanding experience in FEM analyses for large-scale machines that Mecof's experts can fall back on has been translated, for instance, into the development of a great variety of machine types. The result: all machining centers manufactured by the EMCO Group now achieve FEM-optimized stability and precision."

Another example: in 2014/2015, engineers and technicians from all EMCO sites joined forces and developed the Hyperturn 200 Powermill, a combined turning and milling center that provides complete machining of medium-sized complex components in one set-up. Equipped with a main and counter spindle, as well as a powerful milling spindle that is set up on a pivoting axis and used for turning, drilling, milling and gearing operations, the machine is able to manufacture complex workpieces in one set-up. Thus, operators avoid delay times caused by machine changes and increase the precision applied to the product.

"Our developers have succeeded in merging the best of both machining worlds into one machine, transforming a slant-bed turning machine into an extremely versatile traveling column turning and milling center," said Hansch. The concept has been used on machines from the Hyperturn series, including the smaller Hyperturn 65 Powermill and the Hyperturn 100 Powermill.

"EMCO is committed to being the best solution provider when it comes to machining tasks," said Hansch. "All further developments are based on this aspiration. Besides the expansion of combined machining, the integration of automation solutions and innovative measurement technology will play an important role. Industry 4.0 is another important component. In cooperation with our partners, we are already offering different digitization packages including, among other features, methods for predictive maintenance."

"Up to 500 data points relating to individual hardware and software features can already be gathered on a regular basis," continued Hansch. "The changes detected allow us to draw conclusions about the wear of the spindle bearings, for instance. Thus, they can be replaced in a timely manner, which will in turn avoid unplanned downtimes. However, EMCO sees that as the mere beginning of a future that started as early as 75 years ago."

For more information contact:

EMCO Corporation

30475 S Wixom Road, Unit 125

Wixom, MI 48393

248-313-2700

info@emco-usa.com

www.emco-usa.com