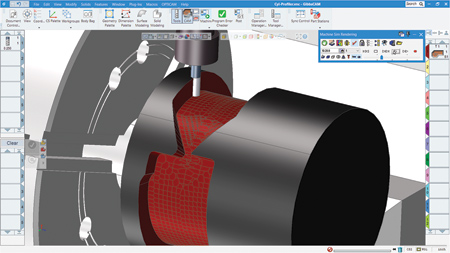

Simulation of Cylindrical Milling from a profile in Slice mode.

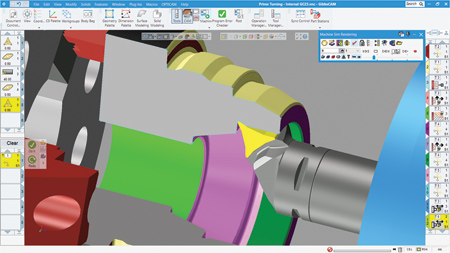

GibbsCAM supports both Roughing and Finishing with Sandvik Coromant's PrimeTurning.

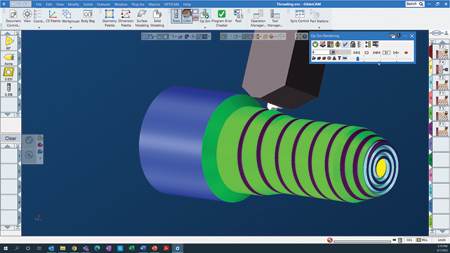

Variable pitch threading applied to the face and outer diameter

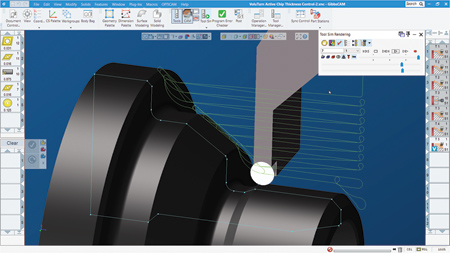

Active Chip Thickness Control in VoluTurn for optimized feedrate

GibbsCAM will showcase its latest Simply Powerful CAM software at IMTS. GibbsCAM product experts will be on hand to give demonstrations and explain new features of the version 2023 release.

GibbsCAM software programs, simulates and controls any CNC machine, from 2D to 5-axis milling, turning, multitask machining (MTM) and wire EDM. Additionally, GibbsCAM in-process probing is designed to reduce handling for total accuracy.

The product bundling of GibbsCAM GO Milling, GO Turning and GO Mill-Turn software levels, and now the new software subscription option, provides customers a flexible way to manage their CNC operations.

Cylindrical milling in GibbsCAM 2023 is easier with direct selection of a "Slice" in the CS depth axis: select a closed profile to machine a cylindrical boss or pocket, or select two loops to machine a groove or ring. New Spiral Boring functionality cuts a spiral out to the full diameter at each Z step, which increases cutting feedrate and depth due to a more consistent tool load. In addition to adding support for high-speed mill tools that cannot plunge or ramp, GibbsCAM 2023 extends the default drill cycle types to include five more: gun drilling, variable peck (full out and chip breaker) and peck tap (full out and chip breaker).

PrimeTurning high performance turning strategy is now built-in for GibbsCAM 2023 for Sandvik Coromant and CoroTurn Prime Type A and Type B inserts. Strategies for Roughing and Finishing allow optimum feedrate adjustment for accurate cutting in either direction.

A new tool type, Multifunction Insert Drill, has been added as a periphery insert that can perform turning and boring, such as Sandvik Coromant CoroDrill 880 series. The Multifunction Insert Drill tool type can seamlessly switch between turning, lathe drilling and mill drilling without retraction or tool change motions. "This is a powerful addition for radial offset drilling," said a company spokesperson.

GibbsCAM GO Turning can now specify Rake and Back Relief for tool inserts to more accurately define the 3D geometry of the tool inserts. A new option for Lathe Drilling with counter-rotating tools commands the live tooling spindle to turn in the opposite direction at a specified RPM to effectively increase spindle speed and boost material removal rates.

The Elliptical Contour process may now be used in elliptical bores inside of solid parts, and also now supports a radial (Xr) stock offset, for ID and OD cutting. A new option in most Turning processes controls Cutting Load Variation to suppress resonance-induced chatter and improve chipbreaking for CNC machines, and in VoluTurn, active control of chip thickness during the cut by varying the feedrate as the instantaneous cut depth changes.

Thread Turning operations are now expanded with Face Threading, Variable Pitch Threading, Multi-pitch and Position Tool Front options. Users can produce a spiral thread on the face of a part, vary pitch threads incrementally per revolution or generate different pitches on a continuous thread with easy control of exact start/end specs in the tool dialog.

GibbsCAM 2022 introduced a new surface modeling command, Extrude. GibbsCAM 2023 is extending this command with a Taper field to match the equivalent solid modeling functionality. New simulation modes-Fixture Visibility and High-Feed Collision Reporting-now extend GibbsCAM accelerated 3D simulation feature set.

Organizing parts is easier to match the way users work. The ability to earmark parts by work group or coordinate system, create operation groups and specify active and inactive operations helps users to track part information throughout the CAM process. User-friendly tabs are added to improve work area limits and let operators customize views and define their default work area.

GibbsCAM will exhibit alongside Cimatron in the Machinery Hall booth 338880 as key partners in the Sandvik Design and Planning Automation division.

For more information contact:

CAMBRIO

1445 Kemper Meadow Drive

Cincinnati, OH 45240

513-674-0005

www.cambrio.com

www.gibbscam.com

www.cimatron.com

IMTS South Building, Level 3

Booth 338880