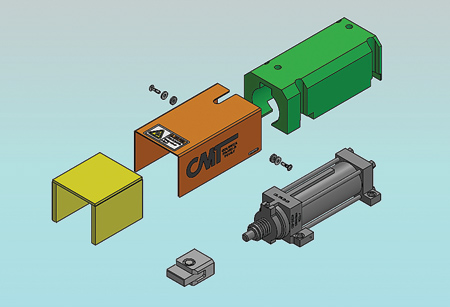

Exploded view of Columbia 751/851 Slide-A-Mark impact marker illustrating the new Sound Abatement System (S.A.S.) sound absorbing system assembly that can reduce average decibels to 67 db.

CMT turn-key robot cell impact marking station for marking left and right-hand cylindrical brackets. Includes Slide-A-Mark impact marker with S.A.S. system, custom pedestal mount frame weldment, valve package, air hoses and non-marring part fixturing.

As industry continues to look for methods to reduce decibel resonance on manufacturing processes, Columbia Marking Tools recently introduced its Sound Abatement System (S.A.S.). Originally developed for a major automotive manufacturer for use in robotic assembly cells, the molded high-density plastic surround cover design enables impact stamping units to significantly reduce resonance decibels, in some cases as low as 67 db.

"Columbia Marking Tools pioneered the development of the double-acting air-operated impact marker, and for many years the patented 8-ton model 751 and high-powered 12-ton model 851 Slide-A-Mark units have been the preferred choice for applying impact marks into a wide variety of materials," said a company spokesperson. "This includes such things as a date stamp and shift codes, QC marks, part numbers, traceability marks, company logos, lot numbers, trademarks and even some staking operations. Over the years, Columbia's impact markers have continued to evolve with improved types of alloys, steels, including high-strength low-alloy (HSLA) steel and different formulations of casting materials to provide more versatility in the range of marking pressure capability."

CMT offers four standard S.A.S. solutions to reduce impact noise:

- S.A.S. marker slip-on form fitting sleeve

- S.A.S. ram sleeve surround

- S.A.S. pliable stamp holder/retainer surround to reduce part resonance

- S.A.S. turn-key marking station with frame (including all of the above).

The sound abatement design includes a lightweight high-density, flame-retardant, plastic sound absorbing cover for the cylinder assembly and an add-on optional sound absorbing ram sleeve designed to accommodate various part stamp tooling lengths depending on the application. The S.A.S. can be purchased as a retrofit package or with the purchase of a new model 751/851 marker. Retrofitting takes just minutes to install.

The S.A.S. can be purchased as a complete stamping unit with a machine frame and an optional sound absorbing high-mass adjustable telescoping pedestal base for robot cell application. Robot manufacturers can specify a junction box with terminal strip pre-wired to part and motion sensors and actuation air valve to make a faster and cleaner installation. Columbia Marking Tools can also provide a manual load/unload station.

Model 751/851 is designed with a cylinder body and bolt-mounting pattern to enhance interchangeability. A variety of keyed air-powered rod and stamp holder styles are available. Model 751/851 can produce a force range of 1/4 to 8 tons. In operation, the marker utilizes a two-stage impact marking sequence where the marker telescopes out to pre-load the stamp or staking tool against the workpiece and then the cylinder fires an internal hammer generating a consistent impact force, which is varied by controlling the actuation air pressure. Fixed internal air passages control the marker's speed. (Typically, a 2-1/2" unit cycle is less than one second).

Model 751/851 is also offered with optional retracted or dual position sensors for return and advanced position of the cylinder stroke to augment their application with automation. By simply loosening a mini dovetail clamp, the advance position sensor can be adjusted to 1". Strokes can range from 2-1/2" to 12" while the marking pressure remains the same anywhere within the stroke.

Slide-A-Marks are powered by factory air and controlled by a standard four-way air valve with a regulator to vary the marking force.

For more information contact:

Columbia Marking Tools

27430 Luckino Dr.

Chesterfield Township, MI 48047

800-469-MARK (6275)

info@columbiamt.com

www.columbiamt.com