The zCAT DCC CMM weighs only 30 lbs. and can take automated, repeatable measurements while being extremely portable.

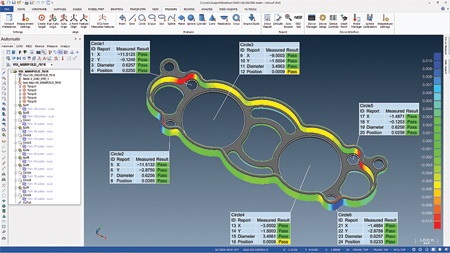

Verisurf software enhances the capabilities of the zCAT DCC CMM through automated programming and control tools. Users are able to quickly create run inspection routines. Any deviation between the part being inspected and the nominal CAD model is displayed in real time using intuitive color mapping and dialog boxes.

zCAT and Verisurf Software, Inc. have announced a portable and automated solution for quality inspection and reporting.

"The bundled solution combines the compact zCAT DCC CMM, offering all the accuracy and functionality of a fixed CMM at a fraction of the size and weight, with the power of Verisurf model-based measurement and inspection software," said a spokesperson. "Under the terms of the program, customers can purchase the solution through established zCAT, Fowler or Verisurf sales channels and receive the same high-level of training, technical and product support. The combined solution delivers a robust and fully programmable, portable, shop floor DCC CMM inspection solution.

The zCAT DCC CMM weighs only 30 lbs. and can take automated, repeatable measurements while being extremely portable. This combination of features makes the zCAT suitable for in-process inspection, so the same person making the part can now measure the part. "The DCC technology, which sets the zCAT apart, enables operators to teach the machine what they want to measure and then permit the device to take over with a level of accuracy that rival larger, more expensive, non-portable, conventional CMMs. Verisurf software further enhances the capabilities of zCAT through automated programming and control tools. The combination of zCAT and Verisurf delivers a measurement and inspection solution of the highest caliber," said Homer Eaton, zCAT inventor and founding partner.

The zCAT system includes the Verisurf CMM Programming & Inspection Software Suite that offers ease-of-use when programming automated inspection programs for CNC CMMs. Using the suite's intuitive graphical interface, users simply point and click on the model features they want to include in their inspection plan, run the plan and post the inspection results.

"Verisurf is committed to open standards and interoperability for more seamless workflow and the ability to maintain a digital thread between design, manufacturing and quality inspection," said Ernie Husted, President of Verisurf Software, Inc. "This zCAT solution is a perfect example of our continuing commitment to bringing portable, automated inspection to the manufacturing shop floor at an affordable price."

For more information contact:

zCAT

www.zcat.com

Verisurf Software, Inc.

4907 E. Landon Dr.

Anaheim, CA 92807

888-713-7201 / 714-970-1683

info@verisurf.com

www.verisurf.com