LASERTEC 125 3D hybrid for workpiece weights of up to 2.000 kg.

The powder bed machines in the LASERTEC SLM series are designed for the productive manufacturing of complex workpieces.

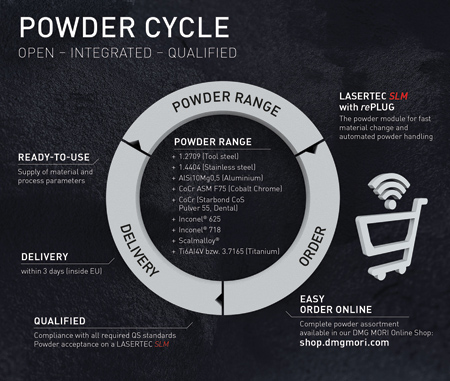

The DMQP program concentrates on open powder selection as well as on a qualified and holistic powder cycle.

DMG MORI recently demonstrated its latest additive manufacturing (AM) solutions, which included the LASERTEC 125 3D hybrid, LASERTEC 30 SLM 2nd Generation and the LASERTEC 12 SLM powder bed process, and the DMU 50 3rd Generation that supplements the additive process chain to include CNC machining.

With the LASERTEC 125 3D hybrid, DMG MORI has expanded its laser deposition welding portfolio to include a model for the maintenance, repair and production of significantly larger parts. Based on the sturdy monoBLOCK series, it is designed for parts measuring up to o 1,250 mm x 745 mm and a workpiece weight of up to 2,000 kg. "The rigid machine construction and high dynamics of the LASERTEC 125 3D hybrid enable the accurate, reliable and at the same time cost-effective complete machining of metallic 3D parts," said a company spokesperson. "Customers can expect high build rates and a repeat accuracy normally associated with CNC machines." The new AM Assistant is part of the innovative software and hardware of the LASERTEC 125 3D hybrid. The hardware includes an integrated thermal imaging camera for continuous thermal monitoring of the entire work area. The AM Assistant also includes the AM Evaluator software, an intelligent downstream evaluation software for 3D process data.

The DMG MORI portfolio in powder bed technology includes the LASERTEC 30 SLM 2nd Generation with its large build chamber of 300 mm x 300 mm x 300 mm and the LASERTEC 12 SLM, which features a focal diameter of 35 µm. It measures 125 mm x 125 mm x 200 mm. One thing that all LASERTEC SLM machines have in common is powder change using the rePLUG powder module. The closed powder circuit provides a high level of work safety. Powder can be easily changed within two hours due to the rePLUG powder module.

The LASERTEC 3D hybrid series is designed for AM of complex prototypes and small series parts as well as for the repair and coating of components. It enables both AM and CNC milling on one machine for 3D components in finished part quality. The portfolio still includes the LASERTEC 65 3D, which is geared solely towards laser deposition welding as a complement to existing machining centers on the shop floor. The LASERTEC SLM series expands the portfolio to include the powder bed method using selective laser melting (SLM). Due to the combination of AM technologies with conventional CNC machines, like the DMU 50 3rd Generation, DMG MORI provides individual needs-based process chains.

DMG MORI has extended the range of DMG MORI Qualified Products to peripheral and accessory components for AM. This includes open powder selection and a qualified and integrated powder circuit. Powder return and recycling with selected DMQP partners provides an economical way of processing expensive powder materials. DMG MORI has validated quality standards on a LASERTEC SLM powder bed machine. Materials in the DMG MORI web shop range from tool steel and stainless steel to aluminum and cobalt chromium to Inconel and titanium, meaning that almost any requirement in the target industries can be covered-worldwide and within just a few working days.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

us.dmgmori.com