Mauro Antolotti, CEO of Beam-IT (right) and Michele Antolotti, General Manager of Beam-IT

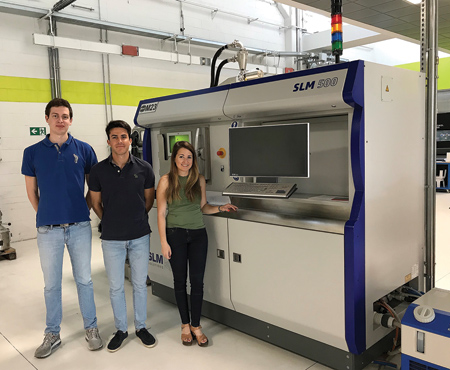

M.Sc. Eng Martina Riccio, AM Process Leader of Beam-IT, and technical team

Beam-IT, an additive manufacturing (AM) service bureau, and SLM Solutions have signed an agreement to deepen their long-term cooperation. Beam-IT expands its product portfolio with two new SLM machines for production and to work on the development of new parameters. The exchange of knowledge regarding new research results and parameter development are planned to create added value for both companies.

"Beam-IT specializes in AM and has the one of the largest AM machine fleets in Europe," said a company spokesperson. "Operating internationally, they have consolidated partnerships with the most prominent companies and research institutions across all industries." The company has now expanded its equipment portfolio to include an additional SLM 280 Selective Laser Melting machine with twin lasers and a quad laser SLM 500, bringing their total of SLM machines to seven.

"We are pleased to announce our cooperation agreement with SLM Solutions and the two additional machines. We regularly produce high-quality parts for our customers using selective laser melting because the SLM technology works efficiently, quickly and, above all, safely. With the expanded capacity of our new multi-laser systems we can also increase our productivity and react to the increased interest in SLM technology from our customers," said Michele Antolotti, General Manager of Beam-IT.

In a joint venture project Beam-IT and SLM Solutions will work on further material parameters for the nickel-based alloys IN939 and IN718, focusing on certain material properties. Targeted parameter sets are necessary to achieve optimal results during the selective laser melting process and Beam-IT's technical experience as an experienced metal AM user will allow them to develop unique parameters with high-quality characteristics. The knowledge-sharing between the two companies during this process will be mutually beneficial in creating a shorter timeframe for parameter testing.

Kamer Geyisi, Sales Manager at SLM Solutions, said, "Beam-IT has a high technical expertise and is working with SLM technology every day. As a partner to our customers throughout the entire AM process chain, SLM Solutions is pleased to share our knowledge with Beam-IT and believe that we will also benefit from their experience with the technology. This partnership approach benefits both our companies, but will also help advance implementation of the technology throughout the entire market."

For more information contact:

SLM Solutions NA, Inc.

48561 Alpha Drive, Suite 300

Wixom, MI 48393

248-243-5400

info@slm-solutions.us

www.slm-solutions.us