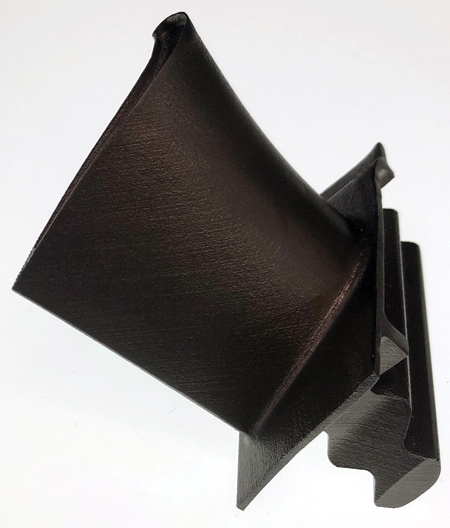

Rocket nozzle produced by Castheon using Onyx In718

Turbine blade made from Onyx In718. The source feedstock to produce the powder was from In718 certified chemistry machined turnings.

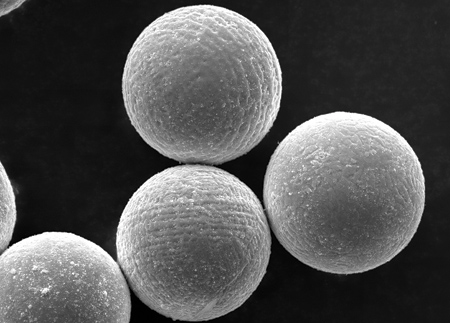

SEM image of Onyx In718, demonstrating spherocity and zero satellites.

6K, a developer of microwave plasma technology for the production of advanced materials used in additive manufacturing (AM), lithium ion batteries and other industrial markets, offers Onyx In718 premium powder for AM. The company recently exhibited Onyx In718 and over 15 other metal alloys, ceramic powders and parts.

"Our mission is to provide a better business case for designers and users of AM parts, and higher performance powders are a critical piece of that mission," said Dr. Aaron Bent, 6K CEO. "Nickel alloy 718, which is critical for aerospace and industrial markets, is the perfect alloy to showcase the unique capability and powerfulness of the 6K powder production process. We are demonstrating powders and parts derived from both subtractive manufacturing certified turnings and powders rejuvenated after laser powder bed processing."

"These powders are not only higher performing, but created from a vastly more sustainable process (less energy/waste) than traditional powder processes, as well as enabling a new 'point of origin' for used powders and parts, necessary for a cost-effective and highly efficient closed loop supply chain," said a company spokesperson.

"Enabled by feedstock sources from reclaimed alloys, combined with the UniMelt microwave plasma system, 6K has the ability to produce powders that exceed competitive technologies, providing higher sphericity, zero porosity, elimination of satellites and high flowability and tap density," continued the spokesperson. "It is the first in the Onyx series of premium powders that have higher performance and can be made from certified chemistry sustainable sources."

"6K powders offer a unique and powerful value proposition for the AM customer and 3D printing companies," said Dr. Youping Gao, CEO of Castheon, a U.S.-based AM research and comprehensive advanced manufacturing solution provider. "Using 6K's Onyx powders, we are achieving higher strengths and elongation than I have seen before. It is also possible to achieve isotropic grain structure after heat treatment, resulting in near isotropic properties (XY and Z directions), which is very exciting."

The Onyx In718 material highlights the first two proof points of 6K's strategy to offer AM powders derived from sustainable sources. One developed from certified chemistry machined turnings, and the second from rejuvenated used AM powder. 6K will extend this in the future to use feedstock created from AM support structures, non-conforming 3D printed parts post-print and other inputs.

"Through its metals reclamation technology, 6K can specifically target the powder size distribution to the AM process of need, including L-PBF, EBM, DED, binder-jetting or MIM, therefore enabling almost 100% UniMelt process yield, as much as three to four times higher than gas atomization," said the spokesperson. 6K will be commissioning a new state-of-the-art AM powder manufacturing plant in Pittsburgh, PA, in Q1/2020 and is currently partnering with customers to pre-qualify and sample Onyx In718 in anticipation of commercial availability in Q2/2020. 6K Additive will follow by launching Ti-AlV64 in Q3/2020.

For more information contact:

6K Additive

1000 South Chester Street

New Cumberland, WV 26047

304-564-5694

info@6kinc.com

www.6Kinc.com