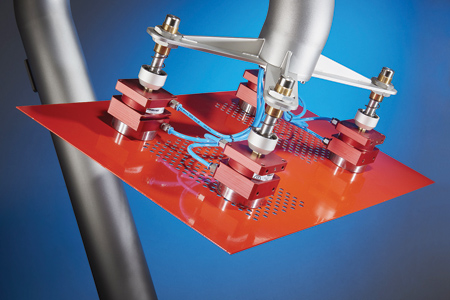

Magnetic Gripper for Robots

March 1, 2020

The magnetic gripper with pad provides a smoothly running production process and is able to handle sheet metal (including perforated) even in a vertical position.

The recently improved magnetic gripper from Goudsmit Magnetics is used for automated pick-up, placement or positioning of steel or other ferromagnetic objects. Examples include: removing sheet metal from presses; bin picking; assembling steel parts; and handling of punched steel parts, blanks and perforated steel sheets in robotic applications.

"The ultralight magnetic gripper is fitted with strong permanent neodymium magnets and is therefore extra safe," said a company spokesperson. It can be used in grippers on robot arms. The handling magnets can be switched on and off by means of compressed air and have a tapped hole interface for attachment to a robot arm, optionally in combination with a spring plunger. See a video at youtu.be/hcXJ98mXHZE

"This makes magnetic grippers an efficient alternative to traditional robotic grippers," said the spokesperson. "Among other things, the system is suitable for lifting and transporting thin steel sheets one by one. The rubber pad at the end ensures that the workpiece does not slide during vertical pick-up and prevents the workpiece from being damaged. This easily installable system is already being used by a number of large car manufacturers and in the sheet metal industry."

"The use of a magnetic gripper on robot arms replaces the traditional vacuum technique," continued the spokesperson. "A disadvantage of vacuum grippers is that they are susceptible to malfunction and subject to wear. Vacuum grippers also have suction cups that must be positioned correctly, because if they are even partially over a hole in the metal sheet they will not grip at all. Electromagnets are not a good solution for this problem, because they are so heavy that they reduce the lifting capacity; a magnetic griper with permanent magnets is considerably lighter. Moreover, the gripper is designed to not wear and provides a longer service life than vacuum grippers."

For more information contact:

Goudsmit Magnetics

info@goudsmitmagnets.com

www.goudsmitmagnets.com

< back