August Behringer, founder of Behringer GmbH

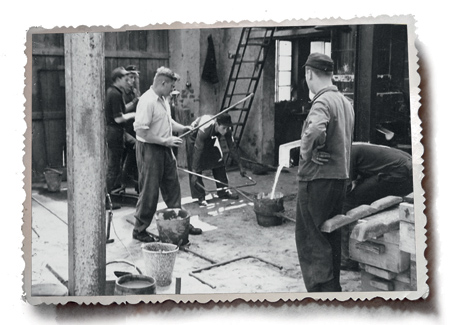

Behringer workshop in 1919, Kirchardt, Germany

Behringer building in 1952

Behringer's new building in Germany

Behringer GmbH is celebrating its 100th anniversary. "Since the founding of the company in 1919, Behringer has developed into the world's leading supplier of innovative sawing technology," said a company spokesperson.

The history of the sawing machine producer started in 1919, when August Behringer founded a small locksmith and mechanical workshop in the village center of Kirchardt, Germany. In the early years, mainly repairs were carried out, but the first machines and equipment for agriculture were also produced.

In the turmoil of the post-war period, need was the driver of invention. Due to a lack of sufficient repair orders, August Behringer responded to a supply gap in his region: many small metalworking companies had no opportunity to separate iron precisely before further processing. So, the entrepreneur produced the first metal hacksaws. Beginning in 1952, the necessary cast iron was made in their own iron foundry. Since that time, Behringer sawing technology and the use of vibration-dampening cast iron components have been closely linked.

In 1962, sons Herbert and Wilhelm Behringer took over the management. With the development of the first bandsaw machines in the 70s and the specialization on robust, column-guided designs, Behringer focused early on the high demands of craft, industry and steel trade for precise, efficient sawing machines. The product range expanded rapidly to include, for example, miter and vertical bandsaws to cover a wider range of applications. The integration of circular saw specialist Eisele in 2000 made Behringer one of the few complete suppliers in the sawing technology market.

Today, Behringer GmbH is an internationally active, medium-sized family business run by the grandchildren of the founder, Rolf and Christian Behringer, in the third generation. "Traditional values, innovative solutions, solid technology and a high-level of vertical integration characterize the company," said the spokesperson. Most of the machines produced are exported to over 80 countries. Sales and service offices in the U.S., France, China and the United Kingdom and over 30 agencies worldwide underline the international focus.

"With extensive investments in the production sites in Kirchardt and Weilheim, Behringer is making 'Fit for Future,'" said the spokesperson. Two new assembly halls and a generous extension to the development departments are being completed. Another focus of the investments is the networking of production facilities and the digitalization of business processes via the in-house BEHR Connect platform. It is designed as a gateway that connects sawing machines, drilling lines or material handling systems and makes it possible to use the wealth of data from the Internet of Things (IoT) with extensive analysis. With add-on modules, the linked production lines are controlled and optimized through numerous processing steps.

For more information contact:

Behringer Saws Inc.

721 Hemlock Road

Morgantown, PA 19543

888-234-7464

sawing@behringersaws.com

www.behringersaws.com