Diran 410MF07 from Stratasys is a nylon-based material for the F370 3D printer. It offers enhanced toughness to withstand the rough handling of tools in the manufacturing setting.

"Addressing the growing demands of engineers and designers to deliver production-grade, custom 3D-printed tooling and parts, Stratasys offers durable, temperature and chemical resistant FDM thermoplastics," said a company spokesperson. "Meeting the specific requirements of 3D printed applications in manufacturing, these materials can accommodate high temperatures and challenging requirements common on the production floor."

Materials recently introduced include Antero 840CN03 for the Stratasys Fortus F900 3D printer, and Diran 410MF07 and ABS-ESD7 for the Stratasys F370 3D printer. Each of these thermoplastics are suited to handle the requirements of manufacturing applications in industries such as automotive and aerospace to engineer advanced 3D printed jigs and fixtures, tooling, prototypes and production parts.

Antero 840CN03 leverages Kepstan PEKK technology from Stratasys strategic supplier Arkema. The new Antero material is formulated to create highly customized tooling and parts with consistent electrostatic discharge (ESD) performance, and is suitable for printing high temperature and chemical-resistant parts with low outgassing and enhanced wear properties.

Suited for aerospace and industrial applications, the Antero material with ESD properties can create strong yet lightweight parts used in frames, panels and components. The material is also being added by Stratasys Direct Manufacturing, the company's contract manufacturing division, as part of its comprehensive material offerings.

"Manufacturing spacecraft poses intense material challenges in the development of parts that exhibit the right attributes," said Brian Kaplun, Senior Manager for Advanced Manufacturing, Lockheed Martin Space. "One of those challenges is getting the right ESD, or electrostatic dissipative properties, among other physical and mechanical characteristics. Stratasys Antero ESD fits our needs for outgassing and electrostatic dissipative properties in a strong but lightweight additive manufacturing material."

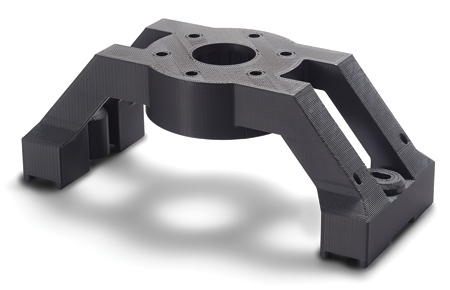

Built for highly durable tooling applications, Diran is a nylon-based material formulated by Stratasys and offered for the Stratasys F370 printer. The new FDM thermoplastic gives manufacturers enhanced toughness and low friction, combined with resistance to hydrocarbon-based chemicals and a smooth surface to offer low sliding resistance. "Diran's toughness is able to withstand the rough handling of tools often common in a manufacturing setting," said the spokesperson.

The ABS-ESD7 thermoplastic, previously only available on the Stratasys Fortus printers, is built for static-sensitive applications to prevent discharge or attraction to other materials like powders, dust and fine particles. "Extending factory floor materials to the Stratasys F370 3D printer, users can capitalize on prototyping and production requirements for low cost and highly customizable parts. Delivering an affordable, ESD-safe material on a platform dedicated to ease of use, repeatability and part accuracy, ABS-ESD7 is suitable for manufacturing tooling applications," said the spokesperson.

"We see growing adoption of 3D printing in production environments, yet engineers and designers struggle with thermoplastics that just cannot match the extreme requirements of manufacturing-based applications," said Adam Pawloski, Vice President of Manufacturing Solutions at Stratasys. "Our thermoplastics can remove these barriers to accelerate adoption of 3D printing in manufacturing settings, allowing users to design and create faster, while minimizing costs often associated with traditional approaches."

For more information contact:

Stratasys Ltd.

7665 Commerce Way

Eden Prairie, MN 55344

800-801-6491

info@stratasys.com

www.stratasys.com