Scanning CMMs and Camio 8.5 CMM Software at WESTEC

September 1, 2019

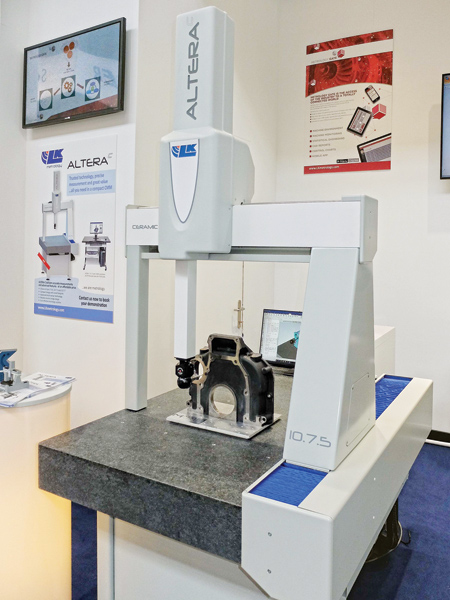

Altera "C" CMM equipped with a Renishaw PH10M probe.

LK Metrology, Inc. will display at WESTEC two different Altera CMM models, one equipped with MODUS software, the other with LK Metrology's CAMIO 8.5 software. A separate demonstration of LK's latest version of CAMIO 8.5 software will be displayed.

The first CMM on display will be the new Altera "C" 10.7.5 CMM equipped with a Renishaw PH10M probe. The 10.7.5 model is the first of three compact CMM sizes that will soon be available. The Altera C is supplied with LK Metrology's CAMIO 8.5 programming, analysis and reporting software, plus a Renishaw articulating head and touch trigger probe that can be easily replaced with a variety of sensors, including Nikon laser scanners. The machine lowers the price of entry to LK CMM multi-sensor inspection technology.

The second CMM on display will be an Altera "M" SCANtek5 10.10.8 CMM equipped with Renishaw's REVO-2 scanning probe and MODUS software. The Altera SCANtek5 is a 5-axis CMM designed for high-speed continuous probe scanning, and applications requiring non-contact vision capability or surface finish analysis. The Altera range of CMMs is LK's most configurable CMM platform available for quality and process control measurement.

"The CAMIO software has become the software of choice for many of the world's largest manufacturers because it allows the user to focus on accelerating lead times and improving product quality," said an LK Metrology spokesperson. "Regardless of whether inspecting stamped, molded or machined parts, CAMIO 8.5 drives accurate and efficient inspection programs for geometric features along with full surface analysis with part-to-CAD comparisons. CAMIO's interoperability across CMM platforms, sensor technology and manufacturing sites becomes its unique advantage."

For more information contact:

LK Metrology, Inc.

12701 Grand River Road

Brighton, MI 48116

810-263-6100

www.lkmetrology.com

WESTEC 2019 Booth 1257

< back