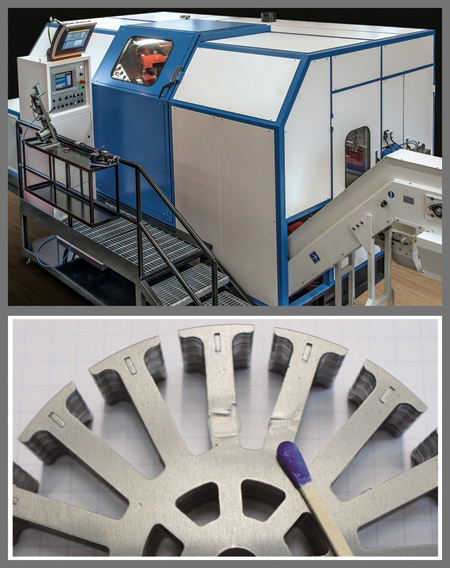

(top) The Marposs X7 "smart" in-process monitoring system from Brankamp helps manufacturers optimize machine efficiency and reduce unplanned downtime. (bottom) Marposs monitoring systems have the ability to detect the slightest punch left on a die, helping avoid needless scrapped parts.

Marposs has announced the availability of its Brankamp X7 "smart" in-process monitoring systems for cold and hot forming, thread rolling and stamping operations. The X7 system's artificial intelligence (AI) capability enables quick machine monitoring set-up and provides an effective way to control machine performance by detecting manufacturing faults as well as part or tool variations. This enables manufacturers to optimize machine efficiency, improve part quality and limit unplanned downtime and tooling costs.

With the X7 process-integrated monitoring solution, manufacturers can streamline set-up and reduce rework, thereby providing increased capacity for additional orders without having to invest in additional presses.

The X7 is operated via a 15" touchscreen with 30 channels capable of monitoring maximum forces, envelope curves and trend progressions, as well as run times, set-up times and downtime or sensitive process areas such as distorted parts or a missed feed.

How the X7 Works

Depending upon the application, sensors are placed either on the machine, in the tooling or in the dies, connecting the press to a Brankamp X7 unit, and enabling users to see at a glance if their machines are running, if their Operational Equipment Efficiency is where it needs to be and what, exactly, is happening at the machine.

The sensors convert energy into electrical signals that monitor tool and machine performances related to the forces applied. Using an adaptive pattern recognition process, the system learns the correct sensor signal profile for a given cycle. If the signals match the learned curve, the process is continuously observed, recording data for supervision of production, batch size, runtime behavior and process trend aiming higher line efficiency. If the signal moves outside of the recognized envelope curve, the system informs the operator of the specific type, cause and location of the fault. If necessary, the system also triggers emergency-stop switching.

Remote Knowledge Sharing

Enabled by the Brankamp FactoryNet 4.0 capability, machine information gleaned from the X7 unit can be passed on directly by the operator to other stakeholders by means of intelligent online communication. Plus, the operator can filter the information, presetting it individually as desired so that each employee receives only the relevant data they need out of the multitude of production process data available. Displayed directly on-screen using a push procedure, the operator gets a real-time overview of the current production status and is able send information by text message or email to any number of people via a mobile number or email address.

For more information contact:

Marposs Corporation

3300 Cross Creek Parkway

Auburn Hills, MI 48326

248-370-0404

marposs@us.marposs.com

www.marposs.com