KVC 821 with rotary plate and trevista reflected light dome illumination unit for challenging dimensional and surface tests on mass-produced parts.

KVC 621 punched part test cell, configured here with five cameras for efficient inspection.

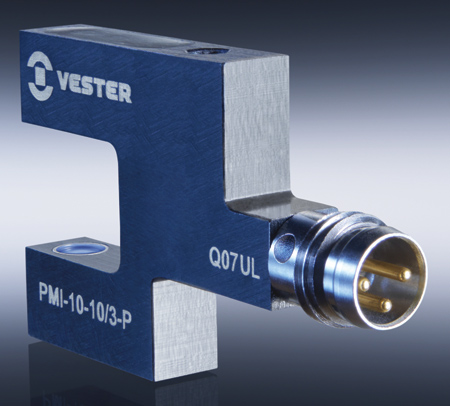

PMI series forked light barrier

Kistler offers dynamic measurement technology, including test automation equipment and optoelectronic sensors added to the offering since the group's acquisition of Vester Elektronik GmbH in August 2017. Application areas for Kistler's extensive range include punching and turning processes as well as mass production in the automotive industry and the medical technology sector.

"Kistler's test automation offering features a varied choice of systems for fast and accurate 100% inspection of series parts," said a company spokesperson. Systems in the KVC 121 series focus on continuous testing of individual parts. These automatic testing and sorting systems feature high throughput rates, making them suitable for contact-free testing of turned, pressed and molded parts. For the feed system, users can choose from a conventional vibratory conveyor or solutions based on modern feed technology. Digital camera measurement technology is used to inspect the parts (such as contact pins) on a test rail, followed by mechanical sorting to help ensure process reliability. The moving test objects pass the test stations at a defined angle to ensure reproducible detection of the smallest dimensional and forming errors, or surface defects measuring only a few hundredths of a millimeter. Various options are available to extend the basic configuration of this modular system, for example, up to four digital cameras with different resolutions can be added.

The KVC 821 system is equipped with a rotary plate that makes it easy to carry out processes, such as attributive surface testing and high-precision testing of individual parts. The feed system is either integrated or separate, depending on the size and weight of the objects for testing. "Cutting-edge optical measurement technology with multiple imaging (Shape from Shading) ensures that even the most complex surface tests are carried out reliably," said the spokesperson. Depending on requirements, the testing station can be extended by adding up to eight digital cameras with different resolutions; additional test modules for functions such as hardness testing can also be included.

The KVC 621 punched part test cell is mainly used in galvanization, punching and injection molding processes. This modular system is chosen by many users to inspect continuous material with constant infeed. The test cell is usually integrated directly into the line as a stand-alone solution, directly downstream of the production process concerned. The feed and the testing principle can also be tailored to individual customer requirements as necessary. Another advantage of the KVC 621: the image processing components can be adapted as required.

"Test assignment set-up is fast and easy due to the KiVision image processing software integrated in every test station," said the spokesperson. "KiVision includes all the methods usually deployed for testing technology with image processing, as well as a wide range of tools and ready-to-use macros for demanding tasks such as measurements with high precision and complex surface inspections. The scope of this software goes far beyond the testing tasks as such: it also enables consistent acquisition of the data-an increasingly important function in view of stricter requirements for product traceability. Data transmission to external CAQ systems and integration into the company's own network provide an ideal solution for central management and downstream processing of test programs and measurement values. Kistler has set up a dedicated competence center for KiVision in Karlsruhe (Germany). The focus is on continuous development of the software so that it can handle even more customer-specific and application-specific processes in the future."

Kistler also offers optical sensors and inductive switches for applications such as feed, ejection and double-sheet control in punching and forming processes that are designed to prevent costly tool breakages. Systems for light barriers of various types-single-beam, multi-beam, laser and infrared and more-help ensure that punching and forming processes run without disruptions. Kistler's sensor technology is also an efficient way of monitoring wear on punching tools, due to strain sensors that perform indirect force measurements. Cycle times can be increased or decreased as required on the basis of data from the sensors.

There is often a need for reliable measurements of the very smallest differences in the dimensions of objects moving at high speeds. This situation calls for precise measurements, with a clearly defined output pulse to trigger the acquisition of measurement data. To achieve this, Kistler makes use of a series of light barriers of different types. These devices are integrated into many of the all-round solutions it developed in response to complex challenges in diverse industrial sectors throughout the world.

For more information contact:

Kistler Instrument Corp.

30280 Hudson Drive

Novi, MI 48377

248-668-6900

sales.us@kistler.com

www.kistler.com