Aluminum part

Steel part

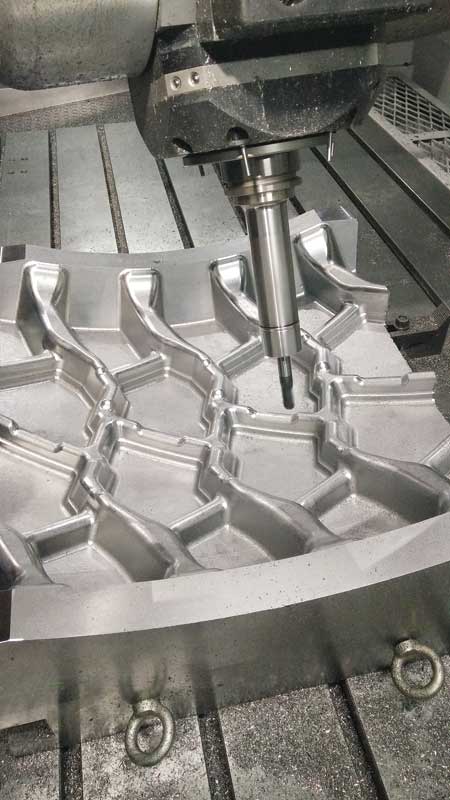

Tire mold

Vision Wide was recently approached by an existing customer, who inquired about a 5-axis head with the ability to cut titanium and aluminum on the same machine.

Vision Wide Engineering reviewed the challenging cutting conditions and offered a 5-axis head solution that would meet and exceed the customer's requirements on either a moving table bridge mill or a high rail gantry machine.

Accuracies were the top requirement-the bridge mill and the gantry mill are both designed with HEIDENHAIN (or Fagor) scale feedback in all axes, laser automatic tool length and diameter measurement with the Blum NT-A4 with kinematic (5-axis) and auto coordinate measurement with the Blum TC-60 (Renishaw products are also available).

The head needed low RPM with high torque for the titanium, and at least 12,000 RPM for the aluminum. Vision Wide's solution was a 45° universal (5-axis) head utilizing dual ballscrews in Z-axis, 15,000 RPM, built-in spindle, HSK-100A, 85 HP with full 5-axis kinematics. The head also comes equipped with a 1,000 PSI coolant-through spindle with rotary union and 90 PSI through spindle air cutting.

Vision Wide machines are equipped with a high level of standard features for all types of industries. Optional items like full top covers, special enclosures, head changers, multiple ATC magazines, voltage stabilizer, dual belt chip conveyors and more are also available.

CNC Systems will coordinate the machine installation, with the factory engineers training on the machine and CNC control (HEIDENHAIN, Siemens or FANUC), third party ISO calibration and provide the customer with all certified machine drawings needed.

For more information contact:

Steven T. Arcari-New England

CNC Systems, Inc.

Office: 207-985-6503

Cell: 860-575-5269

sarcari@cncsystem.com

Brian Arcari-California

Office: 714-838-3999 x 777

Cell: 508-944-5099

brian@cncsystems.com

David M. Valentine-Texas

Office: 817-715-4746

Cell:949-599-5833

valentine@cncsystems.com

Parts: parts@cncsystems.com

Service: service@cncsystems.com

www.cncsystems.com

IMTS South Building, Level 3

Booth 338768

Vision Wide

www.visionwide-tech.com