Micro5 with Feed5 automation is designed for micro-machining.

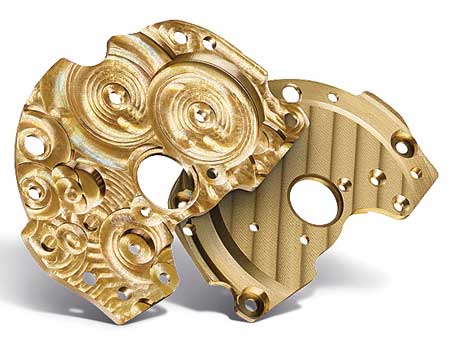

Watchmaking parts done on the Micro5.

Aerospace part on Mill series.

Chiron Group will feature a comprehensive product lineup that will include the new Micro5 and the established Mill 2000.

"From the Chiron Group, customers can expect tailored solutions for small and large parts, with standard automation or as a turn-key solution," said Simon Knecht, VP of Sales and Marketing at Chiron America. "Our expertise in process automation and mastering technologies such as double spindle and multitasking machining with milling and turning positions us to deliver the solution that best meets our customers' requirements."

Chiron Group will showcase the Mill 2000, a VMC designed for 5-axis machining and offering precision, productivity and versatility. The swivel spindle reaches speeds up to 30,000 RPM with 180 Nm of torque. Within the working space dimension of 78.74" x 38.38" x 28.15" (XYZ), multiple clampings or large workpieces are dynamically machined with feedrates up to 246 ft./min. and tool change time of 1.5 s.

With more than 150 units sold in 2024, the new Micro5 offers micro-machining capabilities. With a footprint of 10.76 sq. ft. and an energy consumption of 0.5 kW, it can machine complex and high-quality parts for medical devices, watchmaking, jewelry and highly specialized tiny components. Automated with Feed5 automation system, the modular design of Micro5 can grow step by step from prototyping to large-scale production, delivering high autonomy.

For more information contact:

CHIRON America, Inc.

10950 Withers Cove Park Drive

Charlotte, NC 28278

704-587-9526

info@chironamerica.com

www.chironamerica.us