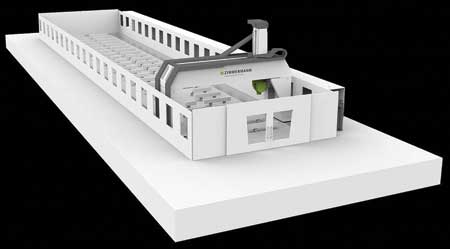

With the new FZG machine line by Zimmermann, large and long components can be manufactured with high precision.

With the new machine line FZG, Zimmermann has added a 5-axis portal milling machine with a low rail gantry to its portfolio, which is suited for processing particularly long components. Accessible from the side, the FZG allows easier loading and unloading processes. The developers utilized the thermo-symmetrical portal concept and modified its basic design. It is engineered to be a stable system that provide high precision, even when processing large and long components.

"Especially in future-oriented industries such as the aerospace, energy or rail sector, producers must be able to efficiently process large and, above all, particularly long components. We have recently received many more requests with these exact requirements," said Daniel Demlang, Technical Leader at Zimmermann.

To meet the needs of the market, Zimmermann developed the FZG machine series in line with customer specifications. For this line of machines, the engineers relied on the concept of the thermo-symmetrical design, which is used with the Zimmermann machine lines FZP and FZU. However, the engineers redesigned its base structure.

"We lowered the machine to ground level, enabling the portal to be moved horizontally in almost any desired length," said Demlang. Zimmerman can adjust this design for any custom application. Therefore, the line is suited for processing complete components, such as wing structures for the aviation industry, entire railway wagon side sections for the rail sector, tanks in the energy sector, exterior components for the aerospace industry, as well as components for the defense industry.

The modular system from Zimmermann acts as the base structure of the new FZG line. It offers many different length and height variants, as well as extensive equipment options, such as process cooling with minimum quantity lubrication or an onboard movable vacuum dust extraction system for abrasive materials and plastics. An onboard movable tool changer is standard. The energy supply and covers are recessed into the floor.

"The thermo-symmetrical design makes the machine less vulnerable in adverse environmental conditions," said Cornelius Kiesel, President of Zimmermann in America. "The idea behind this is that incurring thermal influences can be substantially absorbed by the machine structure itself. To achieve this, we appropriately designed and intelligently arranged all structural and drive unit components, guides and other components responsible for accuracy, for all the machines in our extended portfolio. This way, the structure can expand in noncritical directions."

The centrally guided Z-slide of the portal in double-bridge construction makes the machine particularly stable. By using this design, Zimmermann achieves high rigidity. Since there is no possibility of one-sided temperature rise, accuracy is increased, thus making the machine line suitable for very high-precision applications.

"For us, this combination of thermo-symmetrical machine design and the modified base structure was a logical next step," said Demlang. "Because the core machine relies on proven technology, this development was possible in a relatively short timeframe. Additionally, the synergetic benefits of the FZG, due to the existing portfolio, also have a positive impact on the profitability of the machine."

For more information contact:

Zimmermann Inc.

30587 Century Drive

Wixom, MI 48393

248-956-8511

sales@zimmermann-inc.com

www.zimmermann-inc.com

IMTS South Building, Level 3

Booth 339336