CCS chuck changing system

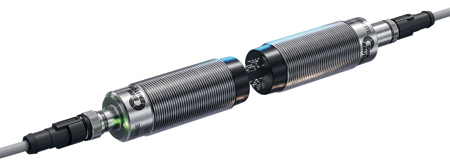

Axial coupler

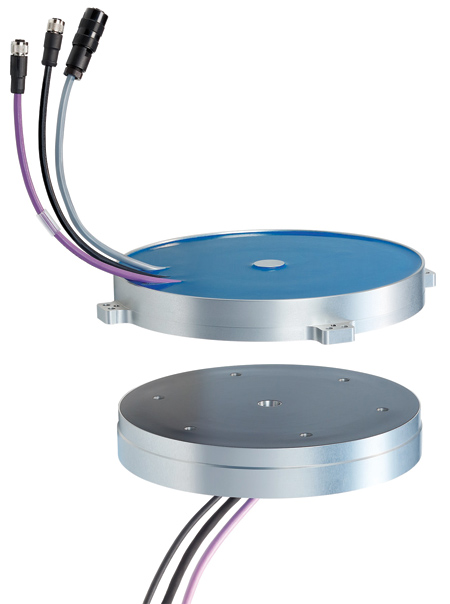

F1800 inductive coupler

Axial coupler

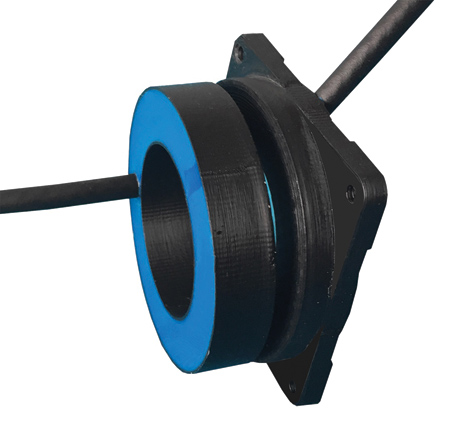

Radial coupler

SMW Autoblok has introduced the CCS chuck changing system. SMW Autoblok has also launched a new company, SMW-Electronics, specializing in products to meet the demands of Industry 4.0.

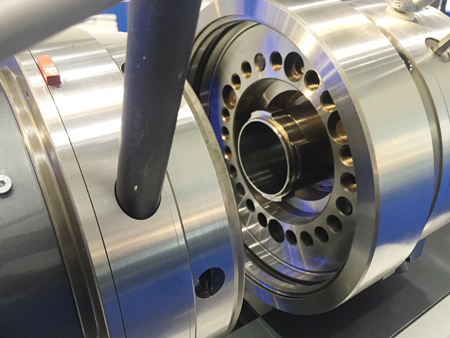

CCS Chuck Changing System

"Providing repeatability that is guaranteed within 10 microns, the CCS can be installed in under three minutes on new or existing lathes, saving time and increasing operator productivity," said a company spokesperson. A standard adapter system provides automatic push off and easy mounting to all types of traditional or custom workholding including 2-jaw chucks, 3-jaw chucks, collet chucks, mandrels and manual fixtures, among others.

With a simple turn of a key, quickly connect workholding devices to the machine spindle and draw tube of the actuating cylinder. This provides operator safety in addition to minimizing machine downtime. A large through hole and a visual safety control of the locking status completes the versatility of the CCS chuck switching system.

SMW-Electronics

SMW-Electronics, headquartered in Meckenbeuren, Germany, will focus on developing innovative products to automate and digitize manufacturing processes to fully utilize Industry 4.0 standards.

"SMW-Electronics leverages core technologies including inductive energy and data transmission, sensors, software and mechatronics to meet the exacting requirements for new markets in industries such as factory automation and material handling, packaging, robotics and electronics manufacturing," said the spokesperson.

Examples of new products already developed by SMW-Electronics include:

- Non-contact couplers for the transmission of energy and data

- Sensors and measuring systems

- Electro-mechanical clamping systems

- Software

- Customized solutions.

"Incorporating Industry 4.0 features into our new electronic products is a huge advantage to our customers. Not only does it increase productivity through automation and process optimization, but it also increases profitability through added production speed," said Peter Helm, Export and Marketing Manager for SMW Autoblok GmbH. "In addition to our standard products, we are also able to fully customize our products to meet customer requirements and specifications for smart manufacturing facilities."

Coupler Systems

SMW-Electronics' flagship product line features non-contact inductive coupler systems that transfer energy (up to 1,800 W) and data between stationary and moving components over an air gap of 4 mm. Inductive couplers reduce the sources of error for loss of communication through the entire production process and are ideal for applications including rotary tables, machining centers, assembly automation, pallet systems, etc. Completely maintenance-free and IP67 rated for harsh, demanding environments, couplers replace cables, contacts or slip rings and are commonly used in sensor technology. Radial couplers for rotary applications are also offered and are available in diameters up to 280 mm with large internal diameters.

Sensors and Measuring Systems

One of SMW-Electronics' new products is the inductive LPS 4.0 position sensor that identifies the exact position of a sensor element wirelessly and with maximum repeat accuracy. The measured value is available via the built-in IO-Link interface or displayed by way of traditional analogue signals (0-10 V or 4-20 mA). The LPS 4.0 is also protected to the IP67 standard and offers enhanced EMC properties.

"For maximizing chuck performance, it is critical to stabilize the machining process, maintaining high repeatability, part quality and safety," said the spokesperson. To help improve and monitor chuck performance, GFT-X 4.0 Grip Force meter and 7" tablet is intuitive and easy to use. The GFT-X-4.0 not only measures the exact gripping force and speed on jaw chucks and collet chucks in static or dynamic mode, but is also an industry tablet with a built-in camera and custom apps to guide the user. The tablet is IP67 rated and has a long battery life, making it suitable for industrial use. The GFT-X 4.0 comes with a variety of measuring heads for jaw chucks, vises and collet chucks. When measuring dynamic gripping forces, the data is transferred from the measuring head to the tablet via Bluetooth.

Mechatronics

SMW's e-motion product line has been developed for digital production and offers a complete range of couplers and software to work with a range of down line systems to handle part holding, workholding actuation components, systems controls, actuators and robotics, to name a few. All e-motion products are based on the same concept of a contact-free inductive coupler system for signal and power transmission.

For industrial applications, the T drive e-motion, as an electro-mechanical actuating unit, is also used to actuate standard chucks. As a further evolution, chucks with a direct electro-mechanical jaw drive have been introduced.

The closed center 4-jaw chuck MM e-motion for mill turn centers has one independent fully controlled and monitored electro-mechanical drive per jaw. This allows for completely new clamping functions like self-centering, compensation or individual jaw movement within one chuck. "Customers will now have a programmable 4-jaw chuck to handle any type of workpiece. The unique feature is the automatic center adjustment for any workpiece shape or configuration," said the spokesperson.

With the addition of SMW-Electronics, the new portfolio supports both new and existing customers by providing solutions to digitize products and achieve greater productivity and flexibility in a variety of manufacturing operations.

For more information contact:

SMW Autoblok

285 Egidi Drive

Wheeling, IL 60090

847-215-0591

autoblok@smwautoblok.com

www.smwautoblok.com

SMW-Electronics

info@smw-electronics.de

www.smw-electronics.com