Robot Package Provides Direct Integration

August 1, 2020

The Haas Robot Package is a fully integrated plug & play robot system that is controlled entirely from the Haas control.

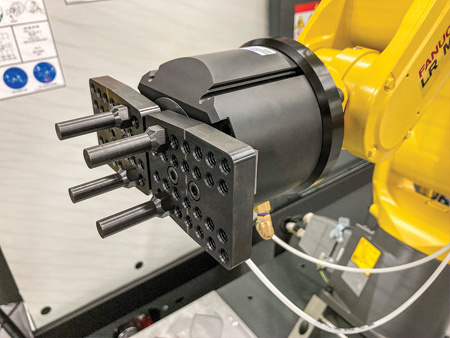

A single gripper is included in the Haas Robot Package. The robot APL grippers can be configured for various part shapes.

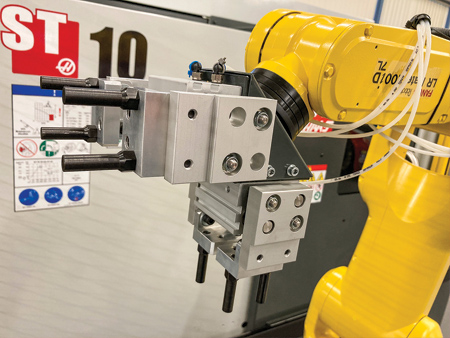

An available double-sided rotating gripper saves time by removing a finished part from the machine and replacing it with a raw piece.

The Haas Robot Package is a fully integrated plug & play robot system for Haas machines. The system is controlled entirely from the Haas control, with no need for PLC connections or a third-party integrator.

With the Haas Robot Interface, the 6-axis robot is set up directly through the Haas control, which guides the operator through the steps necessary to quickly program the robot's motions using the Haas Touchscreen Remote Jog Handle. Answering simple questions, the operator enters basic information by either positioning the part grippers and pushing a single button to record the position, or by entering basic numeric values. The motions are recorded and values are calculated automatically by the control, and the robot is ready for automatic parts loading.

A part management table can be created by setting up a grid pattern template of equally spaced rows and columns. The robot APL grippers can be configured for various part shapes-such as round, hex and square bars-and adjusted or modified.

The robot APL operates in the background during normal machining operations, returning parts to the storage table and retrieving new raw pieces while parts are being machined. The result is near-continuous unattended machining. An available double-sided rotating gripper saves time by removing a finished part from the machine and replacing it with a raw piece.

The Haas Robot Package is available on these machines: VF-1, VF-2, VF2SS, ST-10, ST-15 and ST-20.

For more information contact:

Haas Automation, Inc.

2800 Sturgis Road

Oxnard, CA 93030

800-331-6746

www.HaasCNC.com

< back