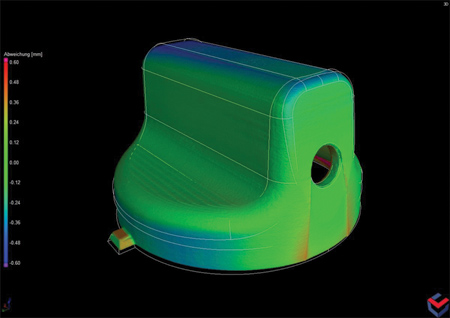

Comparison of manufactured mold-insert part with nominal geometry in Volume Graphics' software.

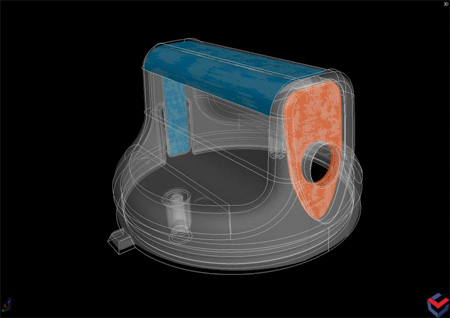

Manufacturing geometry correction module from Volume Graphics adjusts design of mold-insert surfaces to compensate for warpage in the additively manufactured mold prototype.

Volume Graphics has announced its involvement with the Kunststoff-Institut in a second joint project on Rapid Tooling with companies from a range of industries. As a project partner, Volume Graphics brings expertise in quality assurance and process optimization to the team via its advanced industrial computed tomography (CT) data analysis software.

"Working on this project with Kunststoff-Institut and partners is very important to us, because we are convinced that industrial CT can advance the future of rapid tooling," said Christof Reinhart, CEO of Volume Graphics. "We have been following the topic of additive manufacturing (AM) in general, and rapid tooling in particular, for some time now and are working on solutions to increase prototype volumes, speed of design and overall part and process quality."

AM's Growing Role in Rapid Tooling

In tool and mold making, AM (3D printing) is playing an increasingly important role in the quality and economics of high-efficiency metal production tooling with conformal cooling channels, and rapid prototyping of sample parts and plastic mold inserts. Mold inserts are a focus of the Consortium's second project because of their critical importance in strengthening parts and/or encapsulating fabricated components.

The development phase of creating injection molded parts and inserts often requires the production of small-quantity prototypes. Two common approaches are, first, the modeling of sample "presentation" components using a low-end rapid process and, second, the more complicated method of using an aluminum molding tool, where the final part in the prototype production process is completed with an injection molding machine.

However, a new "rapid" method offers improved time and cost savings over aluminum: plastic molds produced through industrial AM that are used for prototyping traditional plastic components with inserts. While the sample output is lower in plastic molds than in aluminum, plastic is proving more than sufficient for prototypes and is less expensive than metal.

CT Data Analysis Software

"Industrial CT has been an indispensable technology in tool and mold inspection for years, allowing non-destructive testing of manufactured components," said a Volume Graphics spokesperson. "Volume Graphics' software provides a much deeper look into CT results, revealing flaws that may be invisible to the naked eye, comparing as-manufactured parts to their original designs and simulating the performance of part geometries to guide design and/or manufacturing corrections. Comparisons between CT and CAD datasets reduce molding tool corrections for defects and warpage to a minimum."

The latest versions of Volume Graphics' CT analysis software packages VGSTUDIO MAX and VGMETROLOGY to provide a Manufacturing Geometry Correction module, which has been specifically developed by Volume Graphics for tool and mold making and AM. Part shrinkage, distortion or other dimensional deviations detected in the CT data set can be transferred to the CAD model of the tool in order to analyze and redesign the relevant contour so that it 3D prints correctly.

"With our Manufacturing Geometry Correction module, we have laid the foundation for many new applications in tool and mold making that can take advantage of improving speed and quality developments in AM," said Reinhart. "This data can be of great use to tool designers for improving both the tool design itself and the 3D printing strategy used to manufacture it."

For more information contact:

Volume Graphics, Inc.

415 Minuet Lane, Suite C

Charlotte, NC 28217

sales-us@volumegraphics.com

704-248-7736

www.volumegraphics.com